A Guide for Choosing the Best Industrial Equipment

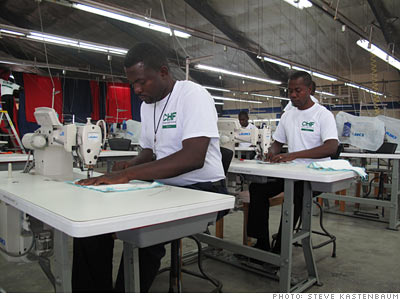

Choosing the best industrial equipment of course depends on the type that you are after. Different industries have different brand names they trust, and while new and expensive equipment may give an assurance of quality, there are second hand or leased machineries that deliver just the same. Thus, a buyer needs to be smart, critical and patient when shopping for industrial needs.

Choosing the best industrial equipment of course depends on the type that you are after. Different industries have different brand names they trust, and while new and expensive equipment may give an assurance of quality, there are second hand or leased machineries that deliver just the same. Thus, a buyer needs to be smart, critical and patient when shopping for industrial needs.

Picking out the best industrial equipment entails a little extra work and a critical eye for substance. A little help and advice here and there also helps a lot in preventing buyer’s remorse later. The following is a step by step guide on choosing the best industrial equipment to get your work done.

1. Determine what you need. What industry are you in? What job do you want done? Different sectors require certain types of equipment for a specific work. The amount of equipment should also be identified. Do you need only one backhoe or fifty pieces of filters? Observing operations will give you an idea of the number of equipment that will suffice for optimum production. This is also important when allocating finances for new equipment.

2. Devise a budget. A financial plan is important for any company, especially when it intends to boost production through purchasing or utilizing additional equipment. When drawing budget plans, it is useful to ask: Will expenditures on additional machinery hurt the company’s overall budget? Will the investment provide sufficient returns the soonest time possible? Can we anticipate the expenses if the machinery unexpectedly breaks down? Considering these things will give you an idea of your company’s financial status as well as whether losses will seriously injure the business.

3. Research. Read magazines, newsletters, or brochures concerning your field. Browse the World Wide Web for informative tips and guides as well as online stores. Chances are you will come across articles which explain the advantages of leasing or buying second hand equipment versus new items, plus pointers (like this one) on how to choose the best industrial basic forklift training pdf equipment. A popular option nowadays is leasing machineries instead of buying new ones. Aside from the flexible payment options, leasing firms offer upgrades of the current machine you are using, as well as the option of buying it out eventually. Second hand equipment is also preferable but a more discerning approach during purchase is required.

Advertisements will give you an idea on reputable companies that manufacture and sell industrial equipment, likewise those that buy and sell.

4. Ask around first. When you have found an eligible reseller or leasing company, it is best to ask people in the business on what they bridgeport mill drawbar know about it. Is the brand trustworthy? Have they purchased a product from them? How were they treated? Is product support available?

5. Check before you check out. Inspect your prospective purchase before handing the money. Is it accurate with the seller’s description? If it is used equipment, ask for a maintenance record. A good reselling …

Any fisherman of any skill level is going to need the right fishing supplies. Depending on which type of fishing you are doing, will dictate the exact supplies you will need to help foster success. There are many places you can find fishing supplies and some that you may not have thought about.

Any fisherman of any skill level is going to need the right fishing supplies. Depending on which type of fishing you are doing, will dictate the exact supplies you will need to help foster success. There are many places you can find fishing supplies and some that you may not have thought about. Providing a wedding candy bar at your wedding reception is an excellent and surprisingly inexpensive way to cater to guests and add another topic of conversation to the day. Typically offered as pretty table spreads or buffet-style set-ups, wedding candy displays

Providing a wedding candy bar at your wedding reception is an excellent and surprisingly inexpensive way to cater to guests and add another topic of conversation to the day. Typically offered as pretty table spreads or buffet-style set-ups, wedding candy displays  Church supplies refer to lecterns, altar candles, communion wine, communion trays, communion tables, wafers and other products used in a church. However, you’ll find that it isn’t only churches that purchase these supplies – lots of different people and organisations will use the products for personal use – people from places all over the world will purchase these supplies so you’ll see them in various locations worldwide.

Church supplies refer to lecterns, altar candles, communion wine, communion trays, communion tables, wafers and other products used in a church. However, you’ll find that it isn’t only churches that purchase these supplies – lots of different people and organisations will use the products for personal use – people from places all over the world will purchase these supplies so you’ll see them in various locations worldwide. Workplace safety is important to companies, workers and the families of the workers. The statistics that exist concerning injuries and illnesses obtained in the workplace and work-related deaths are totally unacceptable. When reviewing the accidents that some people obtain at work it is easy to recognize that many of them could be prevented by the proper use of safety equipment and personal safety gear.

Workplace safety is important to companies, workers and the families of the workers. The statistics that exist concerning injuries and illnesses obtained in the workplace and work-related deaths are totally unacceptable. When reviewing the accidents that some people obtain at work it is easy to recognize that many of them could be prevented by the proper use of safety equipment and personal safety gear. Climbing trees is a challenge for most people to do. You should know that climbing trees is not as simple as it looks. Trees are very dangerous to climb, so you need to have the proper safety equipment for this. It is too dangerous to risk falling from a high elevation and result in internal damage. This seems like a fun thing to do but safety should come first. If you want to engage in tree climbing or any outdoor sports, these tree climbing gear would be very helpful for you to have.

Climbing trees is a challenge for most people to do. You should know that climbing trees is not as simple as it looks. Trees are very dangerous to climb, so you need to have the proper safety equipment for this. It is too dangerous to risk falling from a high elevation and result in internal damage. This seems like a fun thing to do but safety should come first. If you want to engage in tree climbing or any outdoor sports, these tree climbing gear would be very helpful for you to have. Construction equipment is used by a variety of industries all over the world. It can include things like forklifts, excavators, steer loaders, telescopic loaders, and all terrain equipment. With so many different brands manufacturing construction equipment, it can be a hard to know what brand to pick. This article takes a look at some of the most popular and trusted brands who manufacture construction equipment, and it provides some information on the best places to purchase them from.

Construction equipment is used by a variety of industries all over the world. It can include things like forklifts, excavators, steer loaders, telescopic loaders, and all terrain equipment. With so many different brands manufacturing construction equipment, it can be a hard to know what brand to pick. This article takes a look at some of the most popular and trusted brands who manufacture construction equipment, and it provides some information on the best places to purchase them from. If you are interested in bedroom, kitchen or bathroom lighting, there are many options available in the market. No matter the particular needs of your own room, there is verity of lighting that will make your room attractive. Lighting is more important part of your interior decoration; it can help

If you are interested in bedroom, kitchen or bathroom lighting, there are many options available in the market. No matter the particular needs of your own room, there is verity of lighting that will make your room attractive. Lighting is more important part of your interior decoration; it can help  Companies are always looking for the perfect method to manufacture or make products the easier way. There are new systems developed to ensure that entire processes are effective and products are of good quality. It is then very important to look for good woodworking machinery for your industrial needs. There are many reasons why other firms decide to switch from one supplier to another. One good reason is companies

Companies are always looking for the perfect method to manufacture or make products the easier way. There are new systems developed to ensure that entire processes are effective and products are of good quality. It is then very important to look for good woodworking machinery for your industrial needs. There are many reasons why other firms decide to switch from one supplier to another. One good reason is companies  Whether you are an avid craftsmen, a DIY enthusiast or a carpenter in the trade, there are certain wood shop power tools that are necessary to support any type of job that is required. Setting up a workshop can be an easy enough process in creating a good flow and functionality as it is imperative that safety be of utmost priority on your list.

Whether you are an avid craftsmen, a DIY enthusiast or a carpenter in the trade, there are certain wood shop power tools that are necessary to support any type of job that is required. Setting up a workshop can be an easy enough process in creating a good flow and functionality as it is imperative that safety be of utmost priority on your list.