Keeping Things Where They Should Be: Warehouse Management Solutions

Keeping Things Where They Should Be: Warehouse Management Solutions

Storage can plainly mean storing things for future use. Simple as it seems, storing something can be easy when people pertain to grocery items or leftover food. However, it is different when office supplies or numerous resources are concerned. Given the hectic and fast-paced industry that businesses run into, it’s no surprise that mobility and flexibility of storage management is crucial to meet such demand. Manually counting or locating supplies is not as easy as counting all stocks in a given time and space. What it needs is efficient warehouse management software that allows owners to get their storage management system in top shape.

Storage can plainly mean storing things for future use. Simple as it seems, storing something can be easy when people pertain to grocery items or leftover food. However, it is different when office supplies or numerous resources are concerned. Given the hectic and fast-paced industry that businesses run into, it’s no surprise that mobility and flexibility of storage management is crucial to meet such demand. Manually counting or locating supplies is not as easy as counting all stocks in a given time and space. What it needs is efficient warehouse management software that allows owners to get their storage management system in top shape.

Storing operations call for skilled labor in which people or machines are capable enough to do their job from dock retrieval down to the storage area. Monitoring such process also needs to be recorded at least through management of particular computer software. This remains true for accuracy when it comes to information gathered.

Having an updated file can accurately assess if there are available items on the storage area or if the items were delivered. Hence, monitoring of big bulks and high volume of packages through warehouse management system software is highly recommended. Having a particular software also decreases the demand for manual labor, lessening the chances of human error in recording. Above all, having to trust a particular method in organizing all materials with proper accurate labels and positions is doing quality service for clients.

With precision and accuracy, an item can be expected to be delivered at the right time to the right place. If not, they can always be detected in systems where they are recorded. In this sense, the hunting game for storage employees looking for that particular item will not be as tedious at it seems. If a particular item is not found, then it remains to be hidden in the file system until found.

Because storing or delivering equipment cannot be avoided in the business world, efficiency must be taken into consideration. This holds true when warehouse managers take pride in their ability to cope with the stress and pressures of warehouse management. It all starts when items to be stored or shipped are precisely recorded in the system software. In this manner, all details, no matter how small, can be adequately accounted for. Ideally, there are warehouse management software services available in the market. Considering all these, choosing the best one for a company is a good investment.…

The info about the corn stoves delivered here will serve one of two matters: either they will reinforce what you recognize about these stoves or it will teach you something fresh about corn stoves. Both are beneficial results in the field of all types of stoves.

The info about the corn stoves delivered here will serve one of two matters: either they will reinforce what you recognize about these stoves or it will teach you something fresh about corn stoves. Both are beneficial results in the field of all types of stoves. Towing a trailer can be quite an experience especially if you’ve never tried it before. One of the first things you’ll notice is that the vehicle you’re driving doesn’t handle so well. Second, is that your fuel consumption has jumped dramatically and thirdly the one I find scariest is how much even the slightest bit of wind will throw the trailer around.

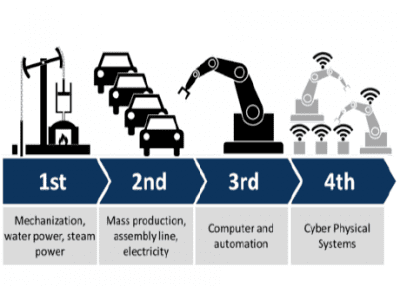

Towing a trailer can be quite an experience especially if you’ve never tried it before. One of the first things you’ll notice is that the vehicle you’re driving doesn’t handle so well. Second, is that your fuel consumption has jumped dramatically and thirdly the one I find scariest is how much even the slightest bit of wind will throw the trailer around. Warehouse managers are under constant pressure to reduce costs without compromising service quality. Technology such as automation, robotics and software has contributed to the evolution of warehouses with the promise of greater efficiency and effectiveness. However, the huge diversity of warehouse operations globally has made the effective use of technology a challenge. Managers understand warehouse operations are about trade-offs such as cost versus service, speed versus accuracy, efficiency versus responsiveness, or volume purchase versus storage cost and availability. Several processes within the warehouse provide opportunities for reducing costs by using advanced techniques and technology.

Warehouse managers are under constant pressure to reduce costs without compromising service quality. Technology such as automation, robotics and software has contributed to the evolution of warehouses with the promise of greater efficiency and effectiveness. However, the huge diversity of warehouse operations globally has made the effective use of technology a challenge. Managers understand warehouse operations are about trade-offs such as cost versus service, speed versus accuracy, efficiency versus responsiveness, or volume purchase versus storage cost and availability. Several processes within the warehouse provide opportunities for reducing costs by using advanced techniques and technology. Most small and medium-sized wholesalers / distributors use a straightforward approach to picking orders. It goes like this:

Most small and medium-sized wholesalers / distributors use a straightforward approach to picking orders. It goes like this: You may be wondering how you can conserve energy, and especially fuel that you use in your vehicle. Many people drive quite a long distance to work or school each day and actually use quite a lot of gas. Even sitting in traffic, your auto is usually on and using it. You may not realize that you can actually cut you r energy use down quite a bit if you are just aware of a few quite simple tips. These are not rocket science, but are just things to think about and consider if you want to save money. Saving on fuel and cutting your use can also be good for our environment. Each person is responsible as a citizen of the earth to take care of it and preserve it in a good way for future generations. Cutting your energy use is one of the ways you can do your part in this effort. And, it should save you quite a bit of money in the mean time if you really get serious about it!

You may be wondering how you can conserve energy, and especially fuel that you use in your vehicle. Many people drive quite a long distance to work or school each day and actually use quite a lot of gas. Even sitting in traffic, your auto is usually on and using it. You may not realize that you can actually cut you r energy use down quite a bit if you are just aware of a few quite simple tips. These are not rocket science, but are just things to think about and consider if you want to save money. Saving on fuel and cutting your use can also be good for our environment. Each person is responsible as a citizen of the earth to take care of it and preserve it in a good way for future generations. Cutting your energy use is one of the ways you can do your part in this effort. And, it should save you quite a bit of money in the mean time if you really get serious about it! There are times when everyone has to deal with power outages. This experience can be very frustrating unless you own a generator. While generators are unable to power everything in the house, they provide a great source of backup power. You will never have to stumble around in the dark when the power goes outs. They are basically small engines that are able to generate electricity.

There are times when everyone has to deal with power outages. This experience can be very frustrating unless you own a generator. While generators are unable to power everything in the house, they provide a great source of backup power. You will never have to stumble around in the dark when the power goes outs. They are basically small engines that are able to generate electricity. Multi fuel stoves are an upcoming trend and the main reason as to why people are switching over to them is the fact that the prices of gas, electricity and other forms of fuel just keeps increasing exponentially.

Multi fuel stoves are an upcoming trend and the main reason as to why people are switching over to them is the fact that the prices of gas, electricity and other forms of fuel just keeps increasing exponentially. Large industrial warehouses have been around as long as there have been roads and lorries large enough to transport the goods to and from in bulk. Managing a very large warehouse, whether it is in Europe, the British Isles, or anywhere else; is a complex task requiring a highly disciplined team and an even more organized logging system. With the rise of electronic scanning devices and computers, an entire new level of efficiency is possible. An integrated network of electronics designed to save money and time is called a warehouse management system.

Large industrial warehouses have been around as long as there have been roads and lorries large enough to transport the goods to and from in bulk. Managing a very large warehouse, whether it is in Europe, the British Isles, or anywhere else; is a complex task requiring a highly disciplined team and an even more organized logging system. With the rise of electronic scanning devices and computers, an entire new level of efficiency is possible. An integrated network of electronics designed to save money and time is called a warehouse management system. Inventory management software can allow you to have a competitive advantage in more ways than one. You have to understand that businesses are able to keep themselves afloat for several reasons.

Inventory management software can allow you to have a competitive advantage in more ways than one. You have to understand that businesses are able to keep themselves afloat for several reasons. Diesel fuel is used for all kinds of industries, be it construction or transport, power generation or agriculture, drilling and exploration or refineries. Every mechanical body seems to be running with the power of petroleum. And this is one reason why Earth’s atmosphere is no longer healthy and refreshing.

Diesel fuel is used for all kinds of industries, be it construction or transport, power generation or agriculture, drilling and exploration or refineries. Every mechanical body seems to be running with the power of petroleum. And this is one reason why Earth’s atmosphere is no longer healthy and refreshing. Just-in-time inventory management systems used in distributions centers are critical for today’s production facilities and raw materials suppliers. Vendors that provide raw, perishable products need access to accurate, real-time inventory management information. This information is critical to meeting their customer’s ever changing production needs. Modern warehousing technologies are designed to track the activities performed in a distribution center and provide the detailed, real time data these vendors require.

Just-in-time inventory management systems used in distributions centers are critical for today’s production facilities and raw materials suppliers. Vendors that provide raw, perishable products need access to accurate, real-time inventory management information. This information is critical to meeting their customer’s ever changing production needs. Modern warehousing technologies are designed to track the activities performed in a distribution center and provide the detailed, real time data these vendors require. Many mid-sized companies assume that automated warehouse management systems are a costly investment they simply can’t afford, but the actual costs of warehouse management solutions are minimal compared to the many ways they can actually help you save money and improve production over time.

Many mid-sized companies assume that automated warehouse management systems are a costly investment they simply can’t afford, but the actual costs of warehouse management solutions are minimal compared to the many ways they can actually help you save money and improve production over time. Are you a man with big ambitions and want to fly high? But your job is not good enough to support your dreams then wholesale business is a good option for you. From the last decade, wholesale business turned out to be one of the most promising businesses with excellent future aspects. Wholesale business is not a complex business with a lot of complications, its very simple business which just requires high ambitions, passions and hard work.

Are you a man with big ambitions and want to fly high? But your job is not good enough to support your dreams then wholesale business is a good option for you. From the last decade, wholesale business turned out to be one of the most promising businesses with excellent future aspects. Wholesale business is not a complex business with a lot of complications, its very simple business which just requires high ambitions, passions and hard work. Why do you need inventory control software in addition to QuickBooks to manage your business? If you perform daily inventory, tracking your inventory data could quickly become overwhelming without inventory software to track data such as items received and item location and quantity after receipt. Using warehouse or inventory management software that integrates with QuickBooks would create an accurate and efficient system for controlling the inventory aspect of a business such as a warehouse or stockroom. The need for an integrated system could be determined by how QuickBooks accounting software is utilized, inventory size and budget.

Why do you need inventory control software in addition to QuickBooks to manage your business? If you perform daily inventory, tracking your inventory data could quickly become overwhelming without inventory software to track data such as items received and item location and quantity after receipt. Using warehouse or inventory management software that integrates with QuickBooks would create an accurate and efficient system for controlling the inventory aspect of a business such as a warehouse or stockroom. The need for an integrated system could be determined by how QuickBooks accounting software is utilized, inventory size and budget. To save gas and fuel costs, increase and improve their miles per gallon rating of fuel economy professional drivers on the road not only drive efficiently and effectively. They also take the time and effort to plan and think ahead to anticipate what is on the roadway and to how they can get there quick but yet with good driving safety and style as well as obtaining good and even better fuel economies. This is especially so when driving up hills and in mountainous roads. In this day and age, with the high and ever increasing prices for gas and diesel fill ups, almost all drivers seem to forever driving towards greater economies and cost reductions when on the road.

To save gas and fuel costs, increase and improve their miles per gallon rating of fuel economy professional drivers on the road not only drive efficiently and effectively. They also take the time and effort to plan and think ahead to anticipate what is on the roadway and to how they can get there quick but yet with good driving safety and style as well as obtaining good and even better fuel economies. This is especially so when driving up hills and in mountainous roads. In this day and age, with the high and ever increasing prices for gas and diesel fill ups, almost all drivers seem to forever driving towards greater economies and cost reductions when on the road. With the cost of gasoline only heading in one direction more of us are now interested in powering our cars and trucks through alternative fuels. The potential of hybrid vehicles and electric only cars seems to have died a natural death as the concept is not one that is sustainable or desirable, at the end of the day any electric vehicle still needs to be plugged into mains power to be charged. One area in which there is still a lot of potential is biofuel. If you want to know how to produce biofuel and become more independent and self reliant then read on.

With the cost of gasoline only heading in one direction more of us are now interested in powering our cars and trucks through alternative fuels. The potential of hybrid vehicles and electric only cars seems to have died a natural death as the concept is not one that is sustainable or desirable, at the end of the day any electric vehicle still needs to be plugged into mains power to be charged. One area in which there is still a lot of potential is biofuel. If you want to know how to produce biofuel and become more independent and self reliant then read on. Fuel Wheels are the one of the leading brands in aftermarket wheels for your truck. They combine unique aesthetics with top of the line quality to bring you some of the most sought after wheels on the market today. They are are manufactured by MHT alloy the leader in aftermarket alloy wheels. The company stemmed from a need for a leader in the off road aftermarket wheel and rim industry.

Fuel Wheels are the one of the leading brands in aftermarket wheels for your truck. They combine unique aesthetics with top of the line quality to bring you some of the most sought after wheels on the market today. They are are manufactured by MHT alloy the leader in aftermarket alloy wheels. The company stemmed from a need for a leader in the off road aftermarket wheel and rim industry. I get many inquiries about how to calculate the carbon footprint of truck transportation. The problem is a fairly simple one to calculate. However, there is one variable that presents a problem. Fuel consumption. Fuel consumption is not constant. It depends on many factors like: age of truck, the general maintenance of the truck, the aerodynamic factor for the truck, if it was travelling up hill, or down hill, if it was a windy day, etc, etc. If your comfortable with an estimate: 6 miles per gallon is a good estimate of what a truck uses on average. Now, the rest is hard data…

I get many inquiries about how to calculate the carbon footprint of truck transportation. The problem is a fairly simple one to calculate. However, there is one variable that presents a problem. Fuel consumption. Fuel consumption is not constant. It depends on many factors like: age of truck, the general maintenance of the truck, the aerodynamic factor for the truck, if it was travelling up hill, or down hill, if it was a windy day, etc, etc. If your comfortable with an estimate: 6 miles per gallon is a good estimate of what a truck uses on average. Now, the rest is hard data… By now, most sizable warehouses have already been automated. When coming to choose a warehouse management system, managers typically seek to replace their legacy system with one that meets changing company needs, addresses increasing operational costs, and integrates seamlessly with new ERP systems, while obtaining quick return on investment (affordability) and to make the implementation of the system as smooth as possible.

By now, most sizable warehouses have already been automated. When coming to choose a warehouse management system, managers typically seek to replace their legacy system with one that meets changing company needs, addresses increasing operational costs, and integrates seamlessly with new ERP systems, while obtaining quick return on investment (affordability) and to make the implementation of the system as smooth as possible. For many years since the invention of the gas car. People have been searching for a way to get better gas mileage. All of this searching has come with many speed bumps. Even with all the speed bumps in the way t was rather easy to get better gas mileage. Using a gas conversion kit not only helped us get better gas mileage. It was also much better for the car.

For many years since the invention of the gas car. People have been searching for a way to get better gas mileage. All of this searching has come with many speed bumps. Even with all the speed bumps in the way t was rather easy to get better gas mileage. Using a gas conversion kit not only helped us get better gas mileage. It was also much better for the car. Russia is the leading producer of fuel oil. They produce more than they can consume, unlike USA that does not produce enough to cater for all consumers. There are a lot of refineries in Russia which can supply up to a million metric tons of fuel oil monthly. A few of the notable suppliers of oil in Russia which can deliver are Lukoil, Bulgarneft, Bashneft, Surgutneftegas, Rosneft etc. These are the best companies to buy fuel from.

Russia is the leading producer of fuel oil. They produce more than they can consume, unlike USA that does not produce enough to cater for all consumers. There are a lot of refineries in Russia which can supply up to a million metric tons of fuel oil monthly. A few of the notable suppliers of oil in Russia which can deliver are Lukoil, Bulgarneft, Bashneft, Surgutneftegas, Rosneft etc. These are the best companies to buy fuel from. Unless you’ve been living under a rock for the last 20 years, you probably have heard about OPEC. OPEC is an acronym for Organization of Petroleum Exporting Countries. Twelve countries – Algeria, Angola, Ecuador, Iran, Iraq, Kuwait, Libya, Nigeria, Qatar, Saudi Arabia, the United Arab Emirates, and Venezuela make up the membership of the cartel.

Unless you’ve been living under a rock for the last 20 years, you probably have heard about OPEC. OPEC is an acronym for Organization of Petroleum Exporting Countries. Twelve countries – Algeria, Angola, Ecuador, Iran, Iraq, Kuwait, Libya, Nigeria, Qatar, Saudi Arabia, the United Arab Emirates, and Venezuela make up the membership of the cartel. In the early years, the existence of gas stations was attributed to its function, which is, dispensing fuel to the vehicles. But now, the face of Gas Stations has changed immensely. They have bow become a retail – marketing sales tool. Supermarkets, couponing, scanning, video displays and eating joints have now become a common function of every gas station that you will visit. From strictly functional they have evolved to be multipurpose.

In the early years, the existence of gas stations was attributed to its function, which is, dispensing fuel to the vehicles. But now, the face of Gas Stations has changed immensely. They have bow become a retail – marketing sales tool. Supermarkets, couponing, scanning, video displays and eating joints have now become a common function of every gas station that you will visit. From strictly functional they have evolved to be multipurpose. It is of course no secret that gas has been getting expensive. With the U.S. dollar going down, there are experts who feel that we may be looking at gas prices in between $4.50 to $5 at the pump next summer. Many countries in Europe already pay much more than that!

It is of course no secret that gas has been getting expensive. With the U.S. dollar going down, there are experts who feel that we may be looking at gas prices in between $4.50 to $5 at the pump next summer. Many countries in Europe already pay much more than that! How many of you forget something that you were going to do today but you won’t remember until tomorrow? I know everyone’s hands would be raised if we were in a fleet fuel seminar. If you forgot what you were going to do today until tomorrow, do you remember where fleet fuel prices have been in the last couple of years?

How many of you forget something that you were going to do today but you won’t remember until tomorrow? I know everyone’s hands would be raised if we were in a fleet fuel seminar. If you forgot what you were going to do today until tomorrow, do you remember where fleet fuel prices have been in the last couple of years? While talking about wholesale business we cannot forget the importance of warehouse and its management. Warehouse management plays a vital role in the success and failure of wholesale suppliers or distributors. Most of the wholesalers face the same problem of getting short of space, too high costs and poor productivity. All these problems are due to a warehouse that is not organized and the wholesalers will not be able to use their space with maximum results. There are also some warehouses with such a layout that it creates hurdles in business. To properly digest the idea of warehouse management we have to first understand what is warehouse? Warehouse is a space that is utilized for providing an adequate environment and protection to the merchandise in bulk storage. Warehouses are meant to store products safely in bulk.

While talking about wholesale business we cannot forget the importance of warehouse and its management. Warehouse management plays a vital role in the success and failure of wholesale suppliers or distributors. Most of the wholesalers face the same problem of getting short of space, too high costs and poor productivity. All these problems are due to a warehouse that is not organized and the wholesalers will not be able to use their space with maximum results. There are also some warehouses with such a layout that it creates hurdles in business. To properly digest the idea of warehouse management we have to first understand what is warehouse? Warehouse is a space that is utilized for providing an adequate environment and protection to the merchandise in bulk storage. Warehouses are meant to store products safely in bulk. Just as a car needs fuel to run, our body needs to be properly hydrated to function during a run. Here are some practices you should consider implementing as part of your life as a runner.

Just as a car needs fuel to run, our body needs to be properly hydrated to function during a run. Here are some practices you should consider implementing as part of your life as a runner. Any business owner that has to operate a warehouse knows that the process cannot operate efficiently if there isn’t a solid system in place. A solid system enables for every phase of the warehouse operations to be solid as possible.

Any business owner that has to operate a warehouse knows that the process cannot operate efficiently if there isn’t a solid system in place. A solid system enables for every phase of the warehouse operations to be solid as possible. The main function of a vehicle’s fuel delivery system is to provide constant flow of fuel to the engine at required volume and pressure. Various mechanical and electrical components constitute a vehicle’s fuel delivery system, each of which has its own function. Proper functioning of every component positively impacts the performance of the engine, while even a little malfunction of any part could seize its operation. Hence, understanding this system enables the user to identify and fix minor issues, helping him minimize the negative impact on the engine’s performance on the whole.

The main function of a vehicle’s fuel delivery system is to provide constant flow of fuel to the engine at required volume and pressure. Various mechanical and electrical components constitute a vehicle’s fuel delivery system, each of which has its own function. Proper functioning of every component positively impacts the performance of the engine, while even a little malfunction of any part could seize its operation. Hence, understanding this system enables the user to identify and fix minor issues, helping him minimize the negative impact on the engine’s performance on the whole. When it comes to saving money for your business, you have to be careful about where you cut the budget. Many companies begin by cutting payroll, but by cutting payroll, you’re putting more stress on other employees. Business owners need to start thinking outside of the box. A great way to save money, for example, is to cut down on fuel costs. In this article, you will learn why fuel management is more important than ever for businesses.

When it comes to saving money for your business, you have to be careful about where you cut the budget. Many companies begin by cutting payroll, but by cutting payroll, you’re putting more stress on other employees. Business owners need to start thinking outside of the box. A great way to save money, for example, is to cut down on fuel costs. In this article, you will learn why fuel management is more important than ever for businesses. Big, spacious, and vital these three words are some in a laundry list of adjectives that properly describes a warehouse. Every product that comes from an adjacent town, a neighboring state, or from across the ocean first lands on this gargantuan storage facility. From there, warehouse staff coordinates the flow of goods to be distributed to retail stores and other establishments.

Big, spacious, and vital these three words are some in a laundry list of adjectives that properly describes a warehouse. Every product that comes from an adjacent town, a neighboring state, or from across the ocean first lands on this gargantuan storage facility. From there, warehouse staff coordinates the flow of goods to be distributed to retail stores and other establishments. Many homes these days still use home heating oil to keep their houses warm in the wintertime, as well as to heat the water in their hot water tank or for their washer and dishwasher. As everyone has probably noticed, anything that is made of an oil product has been going up in price on almost a daily basis.

Many homes these days still use home heating oil to keep their houses warm in the wintertime, as well as to heat the water in their hot water tank or for their washer and dishwasher. As everyone has probably noticed, anything that is made of an oil product has been going up in price on almost a daily basis. It’s not a big secret, from the common man to the business industry that the recession has hurt them all. Through those lean times, companies of all sizes found that they were making changes, scaling back and even losing well more than anticipated. When the economy moves to a slump it hurts, from the smallest to the largest, with everyone else being caught in between. Now they say that when the bottom is hit there is only one way to travel and that is up. As the economy begins to show signs of growth and life, companies are finding that their phones are ringing, orders are coming in and profits are beginning to once again come through. Along with this, comes another change! For those looking to roll with the change, improve their competitive edge and even take their company to the next level they should really look at their warehouse operations! Yes, that’s right, the warehouse processes. Here’s a little more about why:

It’s not a big secret, from the common man to the business industry that the recession has hurt them all. Through those lean times, companies of all sizes found that they were making changes, scaling back and even losing well more than anticipated. When the economy moves to a slump it hurts, from the smallest to the largest, with everyone else being caught in between. Now they say that when the bottom is hit there is only one way to travel and that is up. As the economy begins to show signs of growth and life, companies are finding that their phones are ringing, orders are coming in and profits are beginning to once again come through. Along with this, comes another change! For those looking to roll with the change, improve their competitive edge and even take their company to the next level they should really look at their warehouse operations! Yes, that’s right, the warehouse processes. Here’s a little more about why: Whether you are involved in manufacturing, shipping, or just handle any kind of large volume, you are always looking for ways to make your processing more efficient. After all, greater efficiency means more volume in less time, which means more overall profits. One way to help reduce waste and improve the overall performance of your facilities is by improving current material handling systems, replacing warehouse management systems, or installing new automated conveyor systems if none are in use. How do you know if your setup might be made more efficient? Follow these tips and find out.

Whether you are involved in manufacturing, shipping, or just handle any kind of large volume, you are always looking for ways to make your processing more efficient. After all, greater efficiency means more volume in less time, which means more overall profits. One way to help reduce waste and improve the overall performance of your facilities is by improving current material handling systems, replacing warehouse management systems, or installing new automated conveyor systems if none are in use. How do you know if your setup might be made more efficient? Follow these tips and find out.