Why You Should Look For Industrial Equipment Reviews

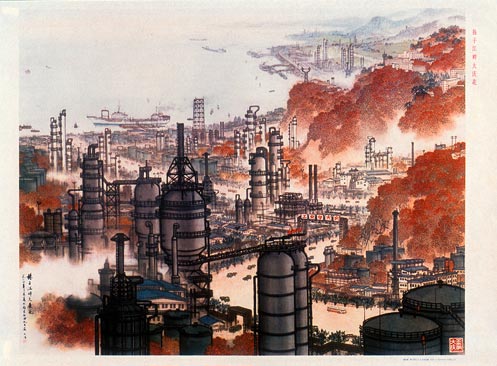

There’s no denying that without industrial equipment, there are so many things that we will be missing out on today.These equipments are being used everywhere. You can find some of these in your home. You can find these in the school, in offices and in big industrial plants. All fields of engineering make use of simple to heavy industrial products. It’s just hard to imagine life without these precious industrial breakthroughs.

There’s no denying that without industrial equipment, there are so many things that we will be missing out on today.These equipments are being used everywhere. You can find some of these in your home. You can find these in the school, in offices and in big industrial plants. All fields of engineering make use of simple to heavy industrial products. It’s just hard to imagine life without these precious industrial breakthroughs.

Industrial equipment reviews are very important for you to know which products are the best buys. Despite the fact that it seem to be found anywhere, it is ironically hard to purchase them. There are so many factors to be considered. Simple industrial products like gauges and electrical tools can be found in hard wares and grocery stores. If you are not content with your purchase, you can even return the product or ask for a refund. However, buying heavy duty equipments like generators, cranes, drilling equipment, vehicles, refrigeration, air conditioners, industrial fan and others is not a joke. Some of these can make you break in the bank without careful planning.

Unfortunately, not all industrial products that you see in the market today are of good quality. There are some companies which are still unable to meet the demands of the customers. Globalization is on the rise and yet, some companies have not yet taken advantage of the technology. head of manufacturing challenges This is the reason why you have to be very careful. You must take time to read industrial equipment reviews. After all, your equipments can affect the success of your company. If you have to buy industrial products for home use, these would affect your comfort and lifestyle.

You need to do a thorough research before you purchase any industrial equipment. Being impulsive or reckless won’t do you any good. A wise buyer always looks for several choices and tries to weigh the differences between wide varieties of choices. If you are how to draw demand and supply curve in excel serious about purchasing equipment, you must keep in mind that you’ll never get out of choices. There are numerous companies today which offer an assortment of industrial machines and equipment. You will learn about these from industrial equipment reviews.

There’s nothing wrong with relying on the brand or company when choosing industrial equipments. Although this is not applicable in some situations, the name of the company can also be a good basis. Some unbiased industrial equipment reviews can give you an idea whether the brand is reputable or not. Most of the time, consumers give testimonials about the company. The credibility of the company is usually directly related to the quality of the products. It is a good idea to find the best companies in the field of industrial equipment.

Industrial equipment reviews can be read in magazines. Engineering magazines often have pages intended for consumer reviews and testimonials. You can also get good unbiased reviews in newspapers. Relying in brochures is not a …

With the collapse in the housing market and the subsequent recession, everyone has had to become an economist. While most people get their information from the news and the stock market analysts, those individuals who work for an industrial supply company automatically have their finger on the pulse of the economy. This is because from their perspective, they see the struggles that our vital industries are undergoing and the ways that companies are finding to survive and even thrive in a challenging economic environment.

With the collapse in the housing market and the subsequent recession, everyone has had to become an economist. While most people get their information from the news and the stock market analysts, those individuals who work for an industrial supply company automatically have their finger on the pulse of the economy. This is because from their perspective, they see the struggles that our vital industries are undergoing and the ways that companies are finding to survive and even thrive in a challenging economic environment. One of the best industrial equipment tips is to be safe. The safety of industrial machinery mostly lies on a well functioning and operating one. Aside from moving vehicles, technologically advanced factories have powerful machines that are stationary like grinders, drills, sanders and Stampers and many more. The knowledge in using and handling these machinery is one thing; the knowledge of its hazards, risks and safety precautions is another. These are two sets of knowledge that one has to internalize to be allowed to handle these kinds of machinery. One should not even think of any kind of horseplay as this machinery can kill in a spit of a second. In fact thousands of industrial workers figure themselves in accidents and death due to machine horseplay. To think of them as toys is like putting one’s life in danger. If one still does not have the appropriate knowledge in handling the machine, he should not attempt to do so.

One of the best industrial equipment tips is to be safe. The safety of industrial machinery mostly lies on a well functioning and operating one. Aside from moving vehicles, technologically advanced factories have powerful machines that are stationary like grinders, drills, sanders and Stampers and many more. The knowledge in using and handling these machinery is one thing; the knowledge of its hazards, risks and safety precautions is another. These are two sets of knowledge that one has to internalize to be allowed to handle these kinds of machinery. One should not even think of any kind of horseplay as this machinery can kill in a spit of a second. In fact thousands of industrial workers figure themselves in accidents and death due to machine horseplay. To think of them as toys is like putting one’s life in danger. If one still does not have the appropriate knowledge in handling the machine, he should not attempt to do so. Often times, people purchasing things like equipment for

Often times, people purchasing things like equipment for  Industrial surplus are the industrial equipments that were used by those companies that had to wrap up their organization because of insolvency or any other economical or relevant crisis. This crisis usually happens when an organization spends a particular amount of money to produce something, but later, after the production, they find that the produced goods will be unable to regain the spent amount of money. The machines that are sold by the industrial surplus shops are, in many cases, of good condition and good quality they are not usually obsolete or archaic. Rather, there is a benefit of choosing these equipments for buying, and that is- these machines have recently been used and, therefore, they are checked; whereas, the fresh machines cannot be checked. So, if you buy any industrial surplus equipment, you will get a checked one at around half of the cost of a new one, but it will most probably provide you almost equal tremendous performance as a new one. Several entrepreneurs, of both new and preceding companies, habitually purchase their necessary equipment from industrial surplus shops just for the reason that they can save almost half of the cost without degrading the quality.

Industrial surplus are the industrial equipments that were used by those companies that had to wrap up their organization because of insolvency or any other economical or relevant crisis. This crisis usually happens when an organization spends a particular amount of money to produce something, but later, after the production, they find that the produced goods will be unable to regain the spent amount of money. The machines that are sold by the industrial surplus shops are, in many cases, of good condition and good quality they are not usually obsolete or archaic. Rather, there is a benefit of choosing these equipments for buying, and that is- these machines have recently been used and, therefore, they are checked; whereas, the fresh machines cannot be checked. So, if you buy any industrial surplus equipment, you will get a checked one at around half of the cost of a new one, but it will most probably provide you almost equal tremendous performance as a new one. Several entrepreneurs, of both new and preceding companies, habitually purchase their necessary equipment from industrial surplus shops just for the reason that they can save almost half of the cost without degrading the quality. Canadian business benefits from commercial leasing and industrial equipment leasing when it comes to asset acquisitions for growth and profits.

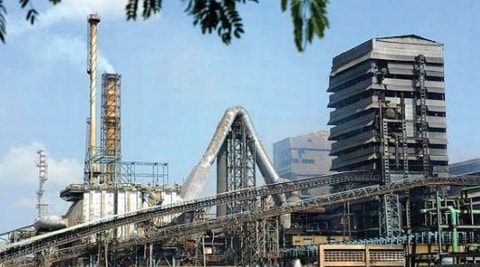

Canadian business benefits from commercial leasing and industrial equipment leasing when it comes to asset acquisitions for growth and profits. Quality industrial equipment is something every construction job should have. Considering how dangerous the work is in the first place, low quality products would only make it more risky for the people behind the scene.

Quality industrial equipment is something every construction job should have. Considering how dangerous the work is in the first place, low quality products would only make it more risky for the people behind the scene. There is great interest in the global community about the worldwide reach of an auction. Bidding facilities are a strategic avenue to auction industrial

There is great interest in the global community about the worldwide reach of an auction. Bidding facilities are a strategic avenue to auction industrial  Crushers are machines that use impact, shear, compression or abrasion to reduce a variety of solid products to a desired particle size range.

Crushers are machines that use impact, shear, compression or abrasion to reduce a variety of solid products to a desired particle size range. The modern world is constantly at risk to various gaseous chemicals. In order to protect life and property from possible harm due to hazardous gases, detection is imperative. Different gases pose risks and the extent of damage depends on the type of gas and the volume of gas spewed. Gases may be classified as combustible or toxic.

The modern world is constantly at risk to various gaseous chemicals. In order to protect life and property from possible harm due to hazardous gases, detection is imperative. Different gases pose risks and the extent of damage depends on the type of gas and the volume of gas spewed. Gases may be classified as combustible or toxic. Buying something used is usually a matter of necessity, but not always. For example, buying industrial woodworking machines secondhand is often better than buying them new. If you are starting a new woodworking business, or upgrading

Buying something used is usually a matter of necessity, but not always. For example, buying industrial woodworking machines secondhand is often better than buying them new. If you are starting a new woodworking business, or upgrading  Choosing the right industrial apparel is vital for implementing an effective personal protective equipment program that will both meet OSHA compliance standards while keeping workers safe on the job. OSHA regulates the use and selection of personal protective industrial equipment and offers a comprehensive guide for every category of hazards and numerous specific applications, with more rules being added as new hazards are identified. The government draws on numerous standards from practical experience and other safety organizations, such as the National Institute of Occupational Safety and Health (NIOSH), in order to produce working rules for employer safety.

Choosing the right industrial apparel is vital for implementing an effective personal protective equipment program that will both meet OSHA compliance standards while keeping workers safe on the job. OSHA regulates the use and selection of personal protective industrial equipment and offers a comprehensive guide for every category of hazards and numerous specific applications, with more rules being added as new hazards are identified. The government draws on numerous standards from practical experience and other safety organizations, such as the National Institute of Occupational Safety and Health (NIOSH), in order to produce working rules for employer safety. There comes a time when standard industrial products do not fit the needs for manufacturing. Whether custom sizes or materials or even entirely reworked industrial equipment are required, most companies will find themselves in the position that they need to order the fabrication of industrial products. There are many factors to consider when shopping for unique equipment solutions, and we will take the time to touch on them in this article.

There comes a time when standard industrial products do not fit the needs for manufacturing. Whether custom sizes or materials or even entirely reworked industrial equipment are required, most companies will find themselves in the position that they need to order the fabrication of industrial products. There are many factors to consider when shopping for unique equipment solutions, and we will take the time to touch on them in this article. Getting the best deals from an auction takes much more than the just being the highest bidder. There are many other things that must be taken into consideration in order to purchase something of great value such as industrial equipment. Just like every other business, the purchasing of industrial equipment requires an ability to sort the good from the bad. Otherwise, it would be very easy to buy sub-standard equipment whatever the price and not realize it until nothing can be done about it.

Getting the best deals from an auction takes much more than the just being the highest bidder. There are many other things that must be taken into consideration in order to purchase something of great value such as industrial equipment. Just like every other business, the purchasing of industrial equipment requires an ability to sort the good from the bad. Otherwise, it would be very easy to buy sub-standard equipment whatever the price and not realize it until nothing can be done about it. Choosing from such a vast selection of industrial supplies in the marketplace can render paralyzed at the best of times if you have no specific selection process to

Choosing from such a vast selection of industrial supplies in the marketplace can render paralyzed at the best of times if you have no specific selection process to  Profitability in the manufacturing business largely depends on the right equipment and sound industrial equipment advice. Investing in an industrial equipment is a major decision for any company and the owners and managers must know how to choose the right equipment at the right time in order to make the purchase worthwhile.

Profitability in the manufacturing business largely depends on the right equipment and sound industrial equipment advice. Investing in an industrial equipment is a major decision for any company and the owners and managers must know how to choose the right equipment at the right time in order to make the purchase worthwhile. Choosing the right industrial apparel is vital for implementing an effective personal protective equipment program that will both meet OSHA compliance standards while keeping workers safe on the job. OSHA regulates the use and selection of personal protective industrial equipment and offers a comprehensive guide for every category of hazards and numerous specific applications, with more rules being added as new hazards are identified. The government draws on numerous standards from practical experience and other safety organizations, such as the National Institute of Occupational Safety and Health (NIOSH), in order to produce working rules for employer safety.

Choosing the right industrial apparel is vital for implementing an effective personal protective equipment program that will both meet OSHA compliance standards while keeping workers safe on the job. OSHA regulates the use and selection of personal protective industrial equipment and offers a comprehensive guide for every category of hazards and numerous specific applications, with more rules being added as new hazards are identified. The government draws on numerous standards from practical experience and other safety organizations, such as the National Institute of Occupational Safety and Health (NIOSH), in order to produce working rules for employer safety. Choosing the best industrial equipment of course depends on the type that you are after. Different industries have different brand names they trust, and while new and expensive equipment may give an assurance of quality, there are second hand or leased machineries that deliver just the same. Thus, a buyer needs to be smart, critical and patient when shopping for industrial needs.

Choosing the best industrial equipment of course depends on the type that you are after. Different industries have different brand names they trust, and while new and expensive equipment may give an assurance of quality, there are second hand or leased machineries that deliver just the same. Thus, a buyer needs to be smart, critical and patient when shopping for industrial needs. Society consumes so much. We like to buy and use but not necessarily re-use. So how can all the things we use be produced swiftly enough to satisfy the latest trends and our cravings for all things new? The answer is industrial machinery.

Society consumes so much. We like to buy and use but not necessarily re-use. So how can all the things we use be produced swiftly enough to satisfy the latest trends and our cravings for all things new? The answer is industrial machinery. Industrial applications involve a number of hardwearing purposes, for which the support of a high powered battery is essentially required. These batteries are bulkier in nature and more durable in comparison to the batteries used for consumer

Industrial applications involve a number of hardwearing purposes, for which the support of a high powered battery is essentially required. These batteries are bulkier in nature and more durable in comparison to the batteries used for consumer  Hazards exist on every job site. In fact, OSHA recorded over 3.5 million injuries in 2008 alone. Businesses need to incorporate the right industrial apparel in conjunction with safe working practices in order to have an injury-free work environment. Industrial equipment and clothing are designed to mitigate hazards, prevent accidents, and reduce the severity of any injuries that may occur. Having a personal protective equipment program in place is essential for every company.

Hazards exist on every job site. In fact, OSHA recorded over 3.5 million injuries in 2008 alone. Businesses need to incorporate the right industrial apparel in conjunction with safe working practices in order to have an injury-free work environment. Industrial equipment and clothing are designed to mitigate hazards, prevent accidents, and reduce the severity of any injuries that may occur. Having a personal protective equipment program in place is essential for every company. Hand injuries in the US send over a million workers to the emergency room every year. The Bureau of Labor and Statistics estimates that over 100,000 workers will lose time on the job as a result of those hand injuries. This is not too surprising considering the fact that the hands are put into harm’s way nearly every day.

Hand injuries in the US send over a million workers to the emergency room every year. The Bureau of Labor and Statistics estimates that over 100,000 workers will lose time on the job as a result of those hand injuries. This is not too surprising considering the fact that the hands are put into harm’s way nearly every day. As green technology develops and becomes more feasible by the year, it is being incorporated into business across the board, from construction to residential use. Environmentally conscious appliances, work practices, building materials, recycling and refurbishing programs, and health initiatives are steadily becoming more available and comprehensive.

As green technology develops and becomes more feasible by the year, it is being incorporated into business across the board, from construction to residential use. Environmentally conscious appliances, work practices, building materials, recycling and refurbishing programs, and health initiatives are steadily becoming more available and comprehensive. Industrial jobs are rewarding for many, but these careers expose workers to big risks. In order to mitigate the risks imposed, employers should provide adequate safety equipment. Companies generally face approval process (as legislated) and included therein is an evaluation of the working facility and availability of safety equipment. There is a wide array of devices that are geared up for the safety of people. These are generally utilized during dire circumstances when human life is threatened. Most items are set just for eye and head protection, yet a whole list of equipment includes apparatuses designed for other areas of the body.

Industrial jobs are rewarding for many, but these careers expose workers to big risks. In order to mitigate the risks imposed, employers should provide adequate safety equipment. Companies generally face approval process (as legislated) and included therein is an evaluation of the working facility and availability of safety equipment. There is a wide array of devices that are geared up for the safety of people. These are generally utilized during dire circumstances when human life is threatened. Most items are set just for eye and head protection, yet a whole list of equipment includes apparatuses designed for other areas of the body. When nations start to get industrialized, several companies tried to enter the scene. More and more countries sought high quality industrial equipment. Without a doubt, high end equipments are needed for a wide range of industrial processes. We won’t come up with all the products and services that we enjoy today without these.

When nations start to get industrialized, several companies tried to enter the scene. More and more countries sought high quality industrial equipment. Without a doubt, high end equipments are needed for a wide range of industrial processes. We won’t come up with all the products and services that we enjoy today without these. Well, they said this would be a jobless recessionary recovery, and the economists were right. Currently major corporations are sitting on hundreds of billions of dollars in cash because they’ve become really good at collecting the money. Their business models are tight, proven, and highly efficient. No matter how much money we give to the poor the wealthy corporations will have that money in less than three transactions.

Well, they said this would be a jobless recessionary recovery, and the economists were right. Currently major corporations are sitting on hundreds of billions of dollars in cash because they’ve become really good at collecting the money. Their business models are tight, proven, and highly efficient. No matter how much money we give to the poor the wealthy corporations will have that money in less than three transactions. Companies are always looking for the perfect method to manufacture or make products the easier way. There are new systems developed to ensure that entire processes are effective and products are of good quality. It is then very important to look for good woodworking machinery for your industrial needs. There are many reasons why other firms decide to switch from one supplier to another. One good reason is companies

Companies are always looking for the perfect method to manufacture or make products the easier way. There are new systems developed to ensure that entire processes are effective and products are of good quality. It is then very important to look for good woodworking machinery for your industrial needs. There are many reasons why other firms decide to switch from one supplier to another. One good reason is companies  There are many factors to consider when you are looking to buy a replacement starter for your heavy-duty equipment. You will want to consider a quality brand like Denso when considering the type of jobs you will need to perform and parts that are best suited to your heavy-duty equipment.

There are many factors to consider when you are looking to buy a replacement starter for your heavy-duty equipment. You will want to consider a quality brand like Denso when considering the type of jobs you will need to perform and parts that are best suited to your heavy-duty equipment. Wind turbines are springing up around the world. In fact, wind power generation is the fastest growing source of alternative energy in the world. Wind turbines are such an attractive alternative because they create no pollution, consume no fossil fuels, and are a renewable resource. Today’s technological advancements in industrial equipment, materials of construction, and tower aerodynamics continues to produce towers with greater generating capacity.

Wind turbines are springing up around the world. In fact, wind power generation is the fastest growing source of alternative energy in the world. Wind turbines are such an attractive alternative because they create no pollution, consume no fossil fuels, and are a renewable resource. Today’s technological advancements in industrial equipment, materials of construction, and tower aerodynamics continues to produce towers with greater generating capacity. For industrial companies, big and small, it is important to have good sources of industrial supply and MRO products so that production and operations will not get hampered because one or two parts are defective and it will usually take longer to have them repaired, or replaced.

For industrial companies, big and small, it is important to have good sources of industrial supply and MRO products so that production and operations will not get hampered because one or two parts are defective and it will usually take longer to have them repaired, or replaced. Quality industrial equipment is something every construction job should have. Considering how dangerous the work is in the first place, low quality products would only make it more risky for the people behind the scene.

Quality industrial equipment is something every construction job should have. Considering how dangerous the work is in the first place, low quality products would only make it more risky for the people behind the scene. Deciding to create a new product from scratch can be a tedious task in the earlier design stages as you will work with a large number of prototypes before you are able to perfect your new products design features and functionality. The raw materials that are used in the early design processes for these prototypes is what determines the success of you products.

Deciding to create a new product from scratch can be a tedious task in the earlier design stages as you will work with a large number of prototypes before you are able to perfect your new products design features and functionality. The raw materials that are used in the early design processes for these prototypes is what determines the success of you products. As green technology develops and becomes more feasible by the year, it is being incorporated into business across the board, from construction to residential use. Environmentally conscious appliances, work practices, building materials, recycling and refurbishing programs, and health initiatives are steadily becoming more available and comprehensive.

As green technology develops and becomes more feasible by the year, it is being incorporated into business across the board, from construction to residential use. Environmentally conscious appliances, work practices, building materials, recycling and refurbishing programs, and health initiatives are steadily becoming more available and comprehensive. Many industrial products are designed with worker safety in mind. Every job site contains hazards and potential accidents that can endanger the safety and well being of workers, so utilizing safety equipment is essential. Industrial products for safety are designed to handle specific hazards and to prevent or mitigate certain accidents and injuries.

Many industrial products are designed with worker safety in mind. Every job site contains hazards and potential accidents that can endanger the safety and well being of workers, so utilizing safety equipment is essential. Industrial products for safety are designed to handle specific hazards and to prevent or mitigate certain accidents and injuries. Used in industrial controls, robotics, and other electro-mechanical devices, a rotary encoder or shaft encoders are responsible for converting the angle at which a shaft is positioned into digital code which computers understand. This makes industrial devices perform more precise operations. Examples of these industrial devices would be flood gates, telescopes, and many more.

Used in industrial controls, robotics, and other electro-mechanical devices, a rotary encoder or shaft encoders are responsible for converting the angle at which a shaft is positioned into digital code which computers understand. This makes industrial devices perform more precise operations. Examples of these industrial devices would be flood gates, telescopes, and many more. Springs are an important tooling component for providing tension and are an all around useful example of industrial equipment supplies. However, those little metal coils can be impractical to work with due to their small size, fragility, and tendency to slip out of the hand when under tension.

Springs are an important tooling component for providing tension and are an all around useful example of industrial equipment supplies. However, those little metal coils can be impractical to work with due to their small size, fragility, and tendency to slip out of the hand when under tension. Replacement parts for sand mixers are important part of foundry equipments. The mixing machines are exposed to a lot of wear and tear and looking for best maintenance options is quite a practical thing to do. Buying new mixers is not possible always because of the cost factor involved. Moreover, it is not an intelligent approach to waste away the whole equipment when few replacements can make up for the damage. Proper functioning is the only expectation from the mixing machines and thus some vendors make money by simply providing replacement parts for the machines that are instrumental in the making of a huge building.

Replacement parts for sand mixers are important part of foundry equipments. The mixing machines are exposed to a lot of wear and tear and looking for best maintenance options is quite a practical thing to do. Buying new mixers is not possible always because of the cost factor involved. Moreover, it is not an intelligent approach to waste away the whole equipment when few replacements can make up for the damage. Proper functioning is the only expectation from the mixing machines and thus some vendors make money by simply providing replacement parts for the machines that are instrumental in the making of a huge building. Industrial machinery is a vast market made up of all different kinds of machinery. Some common types of machinery are: cutting machinery, air compressors, fastener machinery, drilling, industrial engines, printing equipment, and metallurgy machinery. Prices can vary across the board. There also can be a large number of manufacturers. Buyers need a solitary source to sort through all the main suppliers as well as compare prices. Their best bet would be a buyer’s directory.

Industrial machinery is a vast market made up of all different kinds of machinery. Some common types of machinery are: cutting machinery, air compressors, fastener machinery, drilling, industrial engines, printing equipment, and metallurgy machinery. Prices can vary across the board. There also can be a large number of manufacturers. Buyers need a solitary source to sort through all the main suppliers as well as compare prices. Their best bet would be a buyer’s directory. Social media has transformed the way most of the industries connect with their customers. No industry is untouched by the phenomenon. Businesses all over the world have realized the power of expression that social media provides and that it can be used as a tactical ally to connect to customers.

Social media has transformed the way most of the industries connect with their customers. No industry is untouched by the phenomenon. Businesses all over the world have realized the power of expression that social media provides and that it can be used as a tactical ally to connect to customers. Betting on the overall performance of new machines against used ones is a forgone conclusion – or is it? In woodworking, there are some instances when buying the latter is more sensible than buying the former, especially when it features industrial grade design. Unlike hobby grade and mid grade machinery, industrial grade machinery can last for decades, delivering top performance despite frequent use under hash conditions, such as those found in high capacity woodworking factories.

Betting on the overall performance of new machines against used ones is a forgone conclusion – or is it? In woodworking, there are some instances when buying the latter is more sensible than buying the former, especially when it features industrial grade design. Unlike hobby grade and mid grade machinery, industrial grade machinery can last for decades, delivering top performance despite frequent use under hash conditions, such as those found in high capacity woodworking factories. Operating a warehouse can be a tedious task without the correct industrial supplies and in particular, the correct handling equipment to move around the materials and stock in your business storage facility.

Operating a warehouse can be a tedious task without the correct industrial supplies and in particular, the correct handling equipment to move around the materials and stock in your business storage facility. There is great interest in the global community about the worldwide reach of an auction. Bidding facilities are a strategic avenue to auction industrial equipment by being open to the public, allowing a large number of buyers to bid on vehicles with an equal chance of purchasing such equipment.

There is great interest in the global community about the worldwide reach of an auction. Bidding facilities are a strategic avenue to auction industrial equipment by being open to the public, allowing a large number of buyers to bid on vehicles with an equal chance of purchasing such equipment. The success of your factory or shop depends largely on industrial machinery. Use of advanced equipment can result in improved productivity, efficiency, quality control and customer satisfaction. However, high end equipment and machinery can be very expensive. Raising enough capital for purchasing these equipment can be quite difficult especially for small business owners with limited resources.

The success of your factory or shop depends largely on industrial machinery. Use of advanced equipment can result in improved productivity, efficiency, quality control and customer satisfaction. However, high end equipment and machinery can be very expensive. Raising enough capital for purchasing these equipment can be quite difficult especially for small business owners with limited resources. When nations start to get industrialized, several companies tried to enter the scene. More and more countries sought high quality industrial equipment. Without a doubt, high end equipments are needed for a wide range of industrial processes. We won’t come up with all the products and services that we enjoy today without these.

When nations start to get industrialized, several companies tried to enter the scene. More and more countries sought high quality industrial equipment. Without a doubt, high end equipments are needed for a wide range of industrial processes. We won’t come up with all the products and services that we enjoy today without these. It is very common for the average 21st century citizen to take even the most complex of objects and processes for granted and be completely oblivious to the goings on that don’t directly affect him or her. But half of what we do and what we’re used to wouldn’t be possible were it not for the invention of a few vital pieces of industrial equipment. Without them, manufacture on such a high level would simply not be realistic.

It is very common for the average 21st century citizen to take even the most complex of objects and processes for granted and be completely oblivious to the goings on that don’t directly affect him or her. But half of what we do and what we’re used to wouldn’t be possible were it not for the invention of a few vital pieces of industrial equipment. Without them, manufacture on such a high level would simply not be realistic. Hazards exist on every job site. In fact, OSHA recorded over 3.5 million injuries in 2008 alone. Businesses need to incorporate the right industrial apparel in conjunction with safe working practices in order to have an injury-free work environment. Industrial equipment and clothing are designed to mitigate hazards, prevent accidents, and reduce the severity of any injuries that may occur. Having a personal protective equipment program in place is essential for every company.

Hazards exist on every job site. In fact, OSHA recorded over 3.5 million injuries in 2008 alone. Businesses need to incorporate the right industrial apparel in conjunction with safe working practices in order to have an injury-free work environment. Industrial equipment and clothing are designed to mitigate hazards, prevent accidents, and reduce the severity of any injuries that may occur. Having a personal protective equipment program in place is essential for every company.