Industrial Supplies – Types of Raw Materials

Deciding to create a new product from scratch can be a tedious task in the earlier design stages as you will work with a large number of prototypes before you are able to perfect your new products design features and functionality. The raw materials that are used in the early design processes for these prototypes is what determines the success of you products.

Deciding to create a new product from scratch can be a tedious task in the earlier design stages as you will work with a large number of prototypes before you are able to perfect your new products design features and functionality. The raw materials that are used in the early design processes for these prototypes is what determines the success of you products.

Plastics are in most cases durable enough to handle flexibility and sustainable strength for small products that do not need to experience extreme loads and forces of pressure. Deciding on a suitable plastic for your product due to a specific breaking strain means that an industrial supplies company would need to carry a large variety of strengths and flexibility in their plastics to cater for as many intended uses for products as you can think of. This is why industrial supply companies are the place to obtain the correct specifications for the raw materials used in your products.

Metal fabrication is another avenue of manufacturer that relies heavily on different microns (thickness) of their raw materials when producing anything from hot water urns to the sheet industrial equipments suppliers metal used in producing vehicle fenders. Consider the weakness and stresses and strains that need to be considered for these raw materials when building metal fabricated products.

The same would apply to wood and specialist timbers that are used in the fabrication of kitchen cupboards, yachts and furniture items as all timber behaves in a different manner when subjected to heat, c old and moisture.

These materials are carefully selected to ensure their longevity when products are created. Many trials are carried out to select the right material for the job. Popping down to your local DIY supplier will not manufacturing process design definition provide you with the quality and diversity need in the manufacturing sector and this is why you can get such a large selection of options for you intended application from an industrial supplies company.…

Applying dental composite for patients with teeth that don’t look the way they used to, yet are still considered to be healthy and stable. People

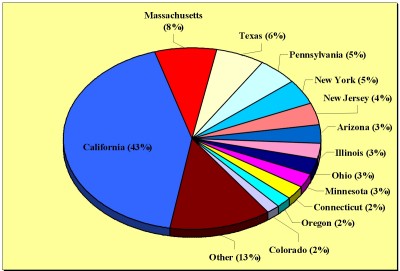

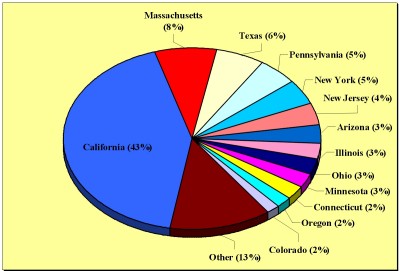

Applying dental composite for patients with teeth that don’t look the way they used to, yet are still considered to be healthy and stable. People  The medical supply industry is about 12,000 companies strong with combined annual revenue of approximately $78 billion. These companies produce instruments, apparatus, and the medical supplies that are used in hospitals and doctor’s offices. Major products range from surgical and medicinal instruments like syringes, hypodermic needles, and catheters to surgical appliances and supplies such as dressings, sutures, and dental devices. The industry is also responsible for the production of lab equipment and furniture as well as ophthalmic goods (glasses and contact lenses).

The medical supply industry is about 12,000 companies strong with combined annual revenue of approximately $78 billion. These companies produce instruments, apparatus, and the medical supplies that are used in hospitals and doctor’s offices. Major products range from surgical and medicinal instruments like syringes, hypodermic needles, and catheters to surgical appliances and supplies such as dressings, sutures, and dental devices. The industry is also responsible for the production of lab equipment and furniture as well as ophthalmic goods (glasses and contact lenses). Often times, people purchasing things like equipment for

Often times, people purchasing things like equipment for  Identifying An Instrumentation Job

Identifying An Instrumentation Job Reason Behind the Law

Reason Behind the Law Crushers are machines that use impact, shear, compression or abrasion to reduce a variety of solid products to a desired particle size range.

Crushers are machines that use impact, shear, compression or abrasion to reduce a variety of solid products to a desired particle size range. The modern world is constantly at risk to various gaseous chemicals. In order to protect life and property from possible harm due to hazardous gases, detection is imperative. Different gases pose risks and the extent of damage depends on the type of gas and the volume of gas spewed. Gases may be classified as combustible or toxic.

The modern world is constantly at risk to various gaseous chemicals. In order to protect life and property from possible harm due to hazardous gases, detection is imperative. Different gases pose risks and the extent of damage depends on the type of gas and the volume of gas spewed. Gases may be classified as combustible or toxic. As a new parent, one of the most important concerns you have is keeping your baby safe. Babies spend the majority of their time at home and this is where you will concentrate your efforts to ensure their safety.

As a new parent, one of the most important concerns you have is keeping your baby safe. Babies spend the majority of their time at home and this is where you will concentrate your efforts to ensure their safety. To make an unforgettable memory picnicking with your companion, decisions have to be made on what to bring, how to bring it, where to go, what to do once you get there, and what to wear. Picnicking is a great way to take a few hours away from the normal pressures

To make an unforgettable memory picnicking with your companion, decisions have to be made on what to bring, how to bring it, where to go, what to do once you get there, and what to wear. Picnicking is a great way to take a few hours away from the normal pressures