Safety Equipment Every Industrial Worker Must Have

Industrial workers must have these in order to protect themselves: eye protection; hearing protection; helmets, boots, and gloves; fire protection; and respirators.

Industrial workers must have these in order to protect themselves: eye protection; hearing protection; helmets, boots, and gloves; fire protection; and respirators.

Health and safety within your occupation is an issue that should never be taken for granted. It’s the responsibility of the employer to provide and necessary medical treatment and financial support for employees who get injured on the job. One way to promote safety and lower your financial is to have some very important protective equipment. Here are some of those:

Eye protection

Many workers are at risk of getting some sort of eye injury while completing their daily work. Many types of injuries, however, are preventable with the use of special eye protection gear. The eye protector varies on the degree of the potential hazard. Glasses may be enough for lesser threats while goggles or full face shields are handy for much bigger risks. Constant use of these items must be maintained to avoid any injury.

Hearing protection

When working in a location when dangerous levels of sound are present, then the use of hearing protection must be always observed. Examples of hearing protector vary from ear plugs to ear muffs and depend on the decibel and frequency level of sound in the worker’s environment. When using a type of hearing protection, it should be used properly. Ear muffs, for example, should fit over the whole ear to provide the best protection.

Helmets, footwear and gloves

The most life threatening among all injuries is head trauma, so the use of a helmet is very helpful in saving one’s life. Hands and feet must be also protected, lead toe boots protect feet from falling objects, and thick shoes can protect soles from sharp ones. Gloves protect hands from burns and contamination.

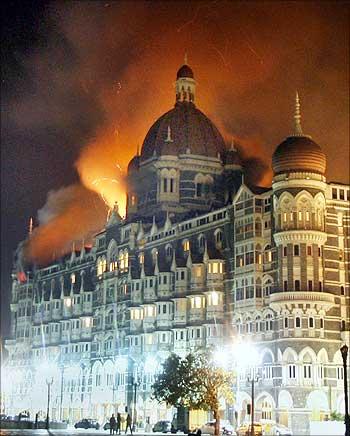

Fire protection

Fire is life-threatening hazard in every work environment. Fire protection items must be readily available at all times. Have a fire extinguisher handy, and make sure all employees know manufacturing equipment examples where it is located and how to operate it. It is impossible to completely fire proof a building, so always remember that the threat of fire is very real. Avoid items made from Asbestos.

Respirators complete tig welding kit

Respirators should be present in working environments where gases and other particulate substances are always found in the air. There are numerous varieties of respirators. Also, have a regular check-up and make necessary precautions to ensure healthy lungs.

Other safety equipment

Aside from the items mentioned, other objects are important, live-saving tools. Among these are hazard warning devices, life jackets, safety belts, safety vest, gas detectors, protective clothing, and reflective safety equipments.

Basically, it’s always the employee’s task to conform with the safety standards and precautions related to work. This, however, must be reciprocal and employers must be willing to support their staff when unfortunate incidents occur and cause injuries to employees.…

Every worksite needs to be clean and orderly in order to function safely and productively. Sanitation is especially important in the food product manufacturing industry. Federal laws and standards are explicit and stringent in mandating how food products are manufactured with specifications on industrial equipment and industrial supplies used in this industry. When it comes to producing foodstuffs, any contamination from bacteria or even dirt can cause health problems for end consumers.

Every worksite needs to be clean and orderly in order to function safely and productively. Sanitation is especially important in the food product manufacturing industry. Federal laws and standards are explicit and stringent in mandating how food products are manufactured with specifications on industrial equipment and industrial supplies used in this industry. When it comes to producing foodstuffs, any contamination from bacteria or even dirt can cause health problems for end consumers. There comes a time when standard industrial products do not fit the needs for manufacturing. Whether custom sizes or materials or even entirely reworked industrial equipment are required, most companies will find themselves in the position that they need to order the fabrication of industrial products. There are many factors to consider when shopping for unique equipment solutions, and we will take the time to touch on them in this article.

There comes a time when standard industrial products do not fit the needs for manufacturing. Whether custom sizes or materials or even entirely reworked industrial equipment are required, most companies will find themselves in the position that they need to order the fabrication of industrial products. There are many factors to consider when shopping for unique equipment solutions, and we will take the time to touch on them in this article. Industrial apparel is more than just a fashion statement; wearing the right clothing on the job site is an essential component of effective personal protective equipment, or PPE. Effective PPE is designed to mitigate workplace hazards and the clothing that workers wear contributes to their own safety on the job. The right industrial apparel and products are essential for effective PPE that meets federal safety guidelines and standards as well.

Industrial apparel is more than just a fashion statement; wearing the right clothing on the job site is an essential component of effective personal protective equipment, or PPE. Effective PPE is designed to mitigate workplace hazards and the clothing that workers wear contributes to their own safety on the job. The right industrial apparel and products are essential for effective PPE that meets federal safety guidelines and standards as well. Every worksite needs to be clean and orderly in order to function safely and productively. Sanitation is especially important in the food product manufacturing industry. Federal laws and standards are explicit and stringent in mandating how food products are manufactured with specifications on industrial equipment and industrial supplies used in this industry. When it comes to producing foodstuffs, any contamination from bacteria or even dirt can cause health problems for end consumers.

Every worksite needs to be clean and orderly in order to function safely and productively. Sanitation is especially important in the food product manufacturing industry. Federal laws and standards are explicit and stringent in mandating how food products are manufactured with specifications on industrial equipment and industrial supplies used in this industry. When it comes to producing foodstuffs, any contamination from bacteria or even dirt can cause health problems for end consumers. Our fathers always taught us to use the right tool for the right job, which still works today, especially in industry. The right industrial supplies make all the difference between running an operation and being a truly efficient business.

Our fathers always taught us to use the right tool for the right job, which still works today, especially in industry. The right industrial supplies make all the difference between running an operation and being a truly efficient business. Often times, people purchasing things like equipment for industry, are having tough times on maintaining it to be in good condition, remain functional and last long. Due to the successive use of the industrial machinery, the performance of the machines can be deteriorated and eventually results in errors and faults. In general, if the machines are not maintained and kept well, productions and other company accomplishments can be compromised and can lead to huge amounts of expenses due to the failure of operations. To avoid this from being happening, below are some of the simple DIY (Do-It-Yourself) steps on how to manage and take care of your industrial machinery:

Often times, people purchasing things like equipment for industry, are having tough times on maintaining it to be in good condition, remain functional and last long. Due to the successive use of the industrial machinery, the performance of the machines can be deteriorated and eventually results in errors and faults. In general, if the machines are not maintained and kept well, productions and other company accomplishments can be compromised and can lead to huge amounts of expenses due to the failure of operations. To avoid this from being happening, below are some of the simple DIY (Do-It-Yourself) steps on how to manage and take care of your industrial machinery: Heat exchangers are used in a variety of industrial processes. More specifically products built by Alfa Laval are used for heating, cooling, separating and transporting products/fluids from one medium to another.

Heat exchangers are used in a variety of industrial processes. More specifically products built by Alfa Laval are used for heating, cooling, separating and transporting products/fluids from one medium to another. Industrial Equipment Leasing (IEL) is a process in which some companies provide various industrial and construction equipments like tools, machineries, earthmovers etc. to other needy

Industrial Equipment Leasing (IEL) is a process in which some companies provide various industrial and construction equipments like tools, machineries, earthmovers etc. to other needy  Manufacturers choose to use and maintain old equipment over purchasing new equipment for several reasons, but the biggest one is that older machines work, and work well. Older industrial equipment is expensive to run and work with, but it can also require a significant investment to replace. The other problem is that sometimes the new machines simply don’t produce consistent, high quality results like older ones do.

Manufacturers choose to use and maintain old equipment over purchasing new equipment for several reasons, but the biggest one is that older machines work, and work well. Older industrial equipment is expensive to run and work with, but it can also require a significant investment to replace. The other problem is that sometimes the new machines simply don’t produce consistent, high quality results like older ones do.