Warehouse Management Systems: Saving Money While Improving Operations

Warehouse Management Systems: Saving Money While Improving Operations

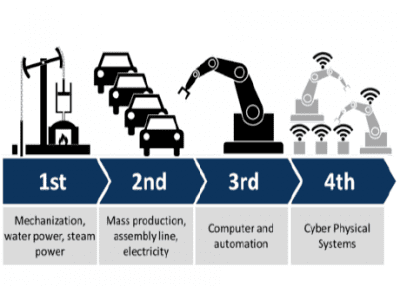

Many mid-sized companies assume that automated warehouse management systems are a costly investment they simply can’t afford, but the actual costs of warehouse management solutions are minimal compared to the many ways they can actually help you save money and improve production over time.

Many mid-sized companies assume that automated warehouse management systems are a costly investment they simply can’t afford, but the actual costs of warehouse management solutions are minimal compared to the many ways they can actually help you save money and improve production over time.

Increase Production And Reduce Product Loss

Warehouse management and automated conveyor systems can operate with minimal supervision on all shifts, including weekends and holidays, with minimal increase in costs. Automation also means no time lost due to employee lateness or no-shows. With automation, the right materials are delivered to the correct areas in an economical, timely fashion, reducing loss during manufacturing production runs or high frequency shipping schedules.

Automation doesn’t just finish or pack products faster; it can also improve the quality of the finished products and minimize product and material loss due to breakage, inconsistent handling or inattention by employees.

Improve Storage Capacity And Maximize Space

Using automated conveyor systems practically guarantees you’ll have more storage space for your products before they’re shipped. Better, more efficient use of space translates into less overhead for additional storage and more efficient fulfillment scenarios for your customers.

Conveyor belt systems can be installed in a variety of configurations in order to take optimal advantage of the existing space. They can hang from the ceiling, be mounted to walls or routed around areas of maximum foot traffic to keep things moving smoothly with wasting space or interfering with key areas needed for other tasks.

Reduce Operation Costs With Conveyor Belt Systems

Businesses that use conveyor belt programs typically reduce the need for employees significantly. Automated machinery can do the work of multiple employees; in fact, for each automated task it would usually take two or three employees to perform the same task. You’ll not only need fewer employees on payroll, you’ll also save money on human resources management, employee training and administrative costs.

Improve Employee Retention And Satisfaction

Employee satisfaction is notoriously low in warehousing environments because of the potential for accidents and the monotony of many job tasks. Ergonomically designed conveyor belt solutions will increase the comfort level for your employees and reduce the incidence of injuries sustained on the job. By using automated systems, you can also diminish the need for employees to do physically demanding tasks while improving your efficiency and safety record, leading to higher employee on the job satisfaction.

More Consistent Results

The tedium and constant repetition required of workers doing specific tasks can lead to errors that cost your business hundreds or even thousands of dollars in losses every month. Where accuracy and repeatability are crucial to your success, automation can produce repeatable, quality results over and over without giving in to fatigue or boredom.

The many advantages of warehouse management and automated conveyor systems quickly outweigh the design and installation costs for all but the smallest of manufacturers and shippers. If you’ve considered installing these programs to improve efficiency, now is the time. There’s …

Are you a man with big ambitions and want to fly high? But your job is not good enough to support your dreams then wholesale business is a good option for you. From the last decade, wholesale business turned out to be one of the most promising businesses with excellent future aspects. Wholesale business is not a complex business with a lot of complications, its very simple business which just requires high ambitions, passions and hard work.

Are you a man with big ambitions and want to fly high? But your job is not good enough to support your dreams then wholesale business is a good option for you. From the last decade, wholesale business turned out to be one of the most promising businesses with excellent future aspects. Wholesale business is not a complex business with a lot of complications, its very simple business which just requires high ambitions, passions and hard work. Why do you need inventory control software in addition to QuickBooks to manage your business? If you perform daily inventory, tracking your inventory data could quickly become overwhelming without inventory software to track data such as items received and item location and quantity after receipt. Using warehouse or inventory management software that integrates with QuickBooks would create an accurate and efficient system for controlling the inventory aspect of a business such as a warehouse or stockroom. The need for an integrated system could be determined by how QuickBooks accounting software is utilized, inventory size and budget.

Why do you need inventory control software in addition to QuickBooks to manage your business? If you perform daily inventory, tracking your inventory data could quickly become overwhelming without inventory software to track data such as items received and item location and quantity after receipt. Using warehouse or inventory management software that integrates with QuickBooks would create an accurate and efficient system for controlling the inventory aspect of a business such as a warehouse or stockroom. The need for an integrated system could be determined by how QuickBooks accounting software is utilized, inventory size and budget. To save gas and fuel costs, increase and improve their miles per gallon rating of fuel economy professional drivers on the road not only drive efficiently and effectively. They also take the time and effort to plan and think ahead to anticipate what is on the roadway and to how they can get there quick but yet with good driving safety and style as well as obtaining good and even better fuel economies. This is especially so when driving up hills and in mountainous roads. In this day and age, with the high and ever increasing prices for gas and diesel fill ups, almost all drivers seem to forever driving towards greater economies and cost reductions when on the road.

To save gas and fuel costs, increase and improve their miles per gallon rating of fuel economy professional drivers on the road not only drive efficiently and effectively. They also take the time and effort to plan and think ahead to anticipate what is on the roadway and to how they can get there quick but yet with good driving safety and style as well as obtaining good and even better fuel economies. This is especially so when driving up hills and in mountainous roads. In this day and age, with the high and ever increasing prices for gas and diesel fill ups, almost all drivers seem to forever driving towards greater economies and cost reductions when on the road. With the cost of gasoline only heading in one direction more of us are now interested in powering our cars and trucks through alternative fuels. The potential of hybrid vehicles and electric only cars seems to have died a natural death as the concept is not one that is sustainable or desirable, at the end of the day any electric vehicle still needs to be plugged into mains power to be charged. One area in which there is still a lot of potential is biofuel. If you want to know how to produce biofuel and become more independent and self reliant then read on.

With the cost of gasoline only heading in one direction more of us are now interested in powering our cars and trucks through alternative fuels. The potential of hybrid vehicles and electric only cars seems to have died a natural death as the concept is not one that is sustainable or desirable, at the end of the day any electric vehicle still needs to be plugged into mains power to be charged. One area in which there is still a lot of potential is biofuel. If you want to know how to produce biofuel and become more independent and self reliant then read on. Fuel Wheels are the one of the leading brands in aftermarket wheels for your truck. They combine unique aesthetics with top of the line quality to bring you some of the most sought after wheels on the market today. They are are manufactured by MHT alloy the leader in aftermarket alloy wheels. The company stemmed from a need for a leader in the off road aftermarket wheel and rim industry.

Fuel Wheels are the one of the leading brands in aftermarket wheels for your truck. They combine unique aesthetics with top of the line quality to bring you some of the most sought after wheels on the market today. They are are manufactured by MHT alloy the leader in aftermarket alloy wheels. The company stemmed from a need for a leader in the off road aftermarket wheel and rim industry. I get many inquiries about how to calculate the carbon footprint of truck transportation. The problem is a fairly simple one to calculate. However, there is one variable that presents a problem. Fuel consumption. Fuel consumption is not constant. It depends on many factors like: age of truck, the general maintenance of the truck, the aerodynamic factor for the truck, if it was travelling up hill, or down hill, if it was a windy day, etc, etc. If your comfortable with an estimate: 6 miles per gallon is a good estimate of what a truck uses on average. Now, the rest is hard data…

I get many inquiries about how to calculate the carbon footprint of truck transportation. The problem is a fairly simple one to calculate. However, there is one variable that presents a problem. Fuel consumption. Fuel consumption is not constant. It depends on many factors like: age of truck, the general maintenance of the truck, the aerodynamic factor for the truck, if it was travelling up hill, or down hill, if it was a windy day, etc, etc. If your comfortable with an estimate: 6 miles per gallon is a good estimate of what a truck uses on average. Now, the rest is hard data… By now, most sizable warehouses have already been automated. When coming to choose a warehouse management system, managers typically seek to replace their legacy system with one that meets changing company needs, addresses increasing operational costs, and integrates seamlessly with new ERP systems, while obtaining quick return on investment (affordability) and to make the implementation of the system as smooth as possible.

By now, most sizable warehouses have already been automated. When coming to choose a warehouse management system, managers typically seek to replace their legacy system with one that meets changing company needs, addresses increasing operational costs, and integrates seamlessly with new ERP systems, while obtaining quick return on investment (affordability) and to make the implementation of the system as smooth as possible.