How to Choose a Warehouse Management System

By now, most sizable warehouses have already been automated. When coming to choose a warehouse management system, managers typically seek to replace their legacy system with one that meets changing company needs, addresses increasing operational costs, and integrates seamlessly with new ERP systems, while obtaining quick return on investment (affordability) and to make the implementation of the system as smooth as possible.

By now, most sizable warehouses have already been automated. When coming to choose a warehouse management system, managers typically seek to replace their legacy system with one that meets changing company needs, addresses increasing operational costs, and integrates seamlessly with new ERP systems, while obtaining quick return on investment (affordability) and to make the implementation of the system as smooth as possible.

Choosing the warehouse management system that matches the company’s needs, requirements, budget, and expectations requires attention and a high degree of professional expertise. The abundance of WMS software solutions and the broad range of warehousing methods and technologies make the choice difficult.

All warehouse management systems aim to meet several goals that as a whole should provide the expected benefits for the client. Knowing what to expect from the system makes the choice between the various WMSs easier. When replacing an existing WMS, a logistics-oriented manager should ask for the following features:

* Improving accuracy of inventory and operations

* Maximizing warehouse space utilization

* Improving order fulfillment

* Providing low ownership cost

* Delivering quick ROI

* Reducing stock while meeting demand

* Lowering decision-making time

* Allowing for quick implementation

To meet these and other expectations requires understanding the key aspects of the future WMS solution, the manner in which these aspects will meet existing needs, and the additional benefits that arise from choosing a specific warehouse management system. The following aspects of any WMS are relevant to the logistics-oriented manager:

Functionality. What does the system offer? Most WMS solutions offer a broad range of functionalities that cover the basic aspects of managing a warehouse. But in addition to inventory management, replenishment, and loading and shipping warehouses also require a more sophisticated set of functionalities such as a billing module, cross-dock capabilities, RFID support, etc.

Flexibility. How easily does the system adapt itself to the client’s needs? A flexible warehouse management system is adaptable to different warehousing scenarios without the need to invest exceptional resources in adaptation. The more flexible the system is, the more easily it integrates in a working warehouse and complies with existing warehouse operations and working methods.

User Friendliness. A WMS must be user friendly. In addition to saving on training costs, user friendliness helps avoid operating mistakes.

ERP Interfacing. The choice of a warehouse management system depends heavily on its ability to integrate with the ERP systems used by the client. Businesses depend on the successful flow of information between company units. The WMS must be able to accurately support this flow of information.

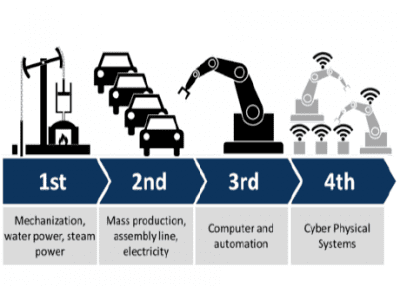

Innovativeness. The technology that underlies the WMS is crucial for its ability to keep abreast of progress in the industry. An outdated system is unable to adapt to future technological requirements, which leads eventually to the need for its replacement.

Disadvantages. Every system has disadvantages. Getting to know the disadvantages of a WMS helps avoid surprises and unexpected costs.

Choosing the right warehouse management system is important. Other issues that require attention are an understanding of key aspects of the system of choice, integration by an experienced supplier, and quality support.