Innovative Construction Design Shaping Tomorrow’s Spaces

Exploring the Future of Innovative Construction Design

Embracing Creativity and Functionality

In the realm of construction, design is not just about aesthetics; it’s about functionality and efficiency. Innovative construction design merges creativity with practicality, creating spaces that are not only visually stunning but also highly functional and conducive to productivity.

Breaking Traditional Boundaries

Gone are the days of cookie-cutter buildings and monotonous designs. Today, construction design is all about breaking traditional boundaries and pushing the limits of creativity. Architects and designers are constantly exploring new materials, technologies, and techniques to create structures that stand out and make a statement.

Adapting to Changing Needs

As our society evolves, so do our needs and preferences. Innovative construction design is all about adapting to these changes and creating spaces that meet the demands of modern living. Whether it’s designing sustainable buildings, flexible workspaces, or smart homes, designers are constantly innovating to stay ahead of the curve.

Harnessing the Power of Technology

Technology has revolutionized the way we approach construction design. From advanced modeling software to 3D printing technology, architects and designers have a wealth of tools at their disposal to bring their visions to life. These technologies not only streamline the design process but also allow for greater precision and efficiency.

Prioritizing Sustainability and Resilience

In today’s environmentally conscious world, sustainability and resilience are top priorities in construction design. Architects and designers are incorporating green building practices, renewable energy sources, and resilient design strategies to minimize environmental impact and enhance long-term durability.

Creating Spaces for the Future

Innovative construction design is not just about the present; it’s about creating spaces that will stand the test of time. Architects and designers are mindful of future trends and developments, designing buildings that are flexible, adaptable, and future-proof. Whether it’s designing for climate change or incorporating the latest technology trends, they’re always thinking ahead.

Fostering Collaboration and Creativity

Collaboration is at the heart of innovative construction design. Architects, engineers, builders, and clients work together to bring a shared vision to life, leveraging their collective expertise and creativity to create truly exceptional spaces. By fostering a collaborative environment, designers can push the boundaries of what’s possible and deliver innovative solutions.

Celebrating Diversity in Design

Innovative construction design celebrates diversity in all its forms. From iconic skyscrapers to community-oriented housing developments, each project tells a unique story shaped by cultural influences, architectural styles, and individual aspirations. Embracing this diversity enriches our built environment and fosters a sense of belonging for all.

Investing in Education and Training

The future of construction design relies on a skilled and knowledgeable workforce. Investing in education and training programs ensures that architects, engineers, and designers are equipped with the latest tools, techniques, and best practices. By nurturing talent and fostering innovation, we pave the way for continued advancement in the field.

Building a Better Future Together

Innovative construction design plays a crucial role in shaping the world we inhabit. By embracing creativity, collaboration, and technology, we can create spaces that inspire, empower, and

Getting a PhD in Industrial Technology gives you the extra edge. It allows you to specialize on highly technical manufacturing processes and its strategies. Basically, one in this field should have a strong interest in mathematics, and they should also be keen on research and problem-solving skills regarding issues such as operations, maintenance, and management. With that and some proper planning, you are able to get that highly desired qualification.

Getting a PhD in Industrial Technology gives you the extra edge. It allows you to specialize on highly technical manufacturing processes and its strategies. Basically, one in this field should have a strong interest in mathematics, and they should also be keen on research and problem-solving skills regarding issues such as operations, maintenance, and management. With that and some proper planning, you are able to get that highly desired qualification. The manufacturing of products requires specific knowledge in the operation, management, and repair of technical systems. The process of production requires individuals that understand the technology behind service systems. Students can enter online training in industrial technology and learn how to work with these systems and other employees.

The manufacturing of products requires specific knowledge in the operation, management, and repair of technical systems. The process of production requires individuals that understand the technology behind service systems. Students can enter online training in industrial technology and learn how to work with these systems and other employees. Obtaining an education in the field of industrial technology can be done through accredited online schools and colleges. Students are able to receive the training that will prepare them for a number of exciting careers in the industry. Online learning programs offer students with the opportunity to obtain a variety of accredited degrees and certificates. Specialized areas of study can be entered by those looking to gain an education in specific areas of the field.

Obtaining an education in the field of industrial technology can be done through accredited online schools and colleges. Students are able to receive the training that will prepare them for a number of exciting careers in the industry. Online learning programs offer students with the opportunity to obtain a variety of accredited degrees and certificates. Specialized areas of study can be entered by those looking to gain an education in specific areas of the field. Career training opportunities for industrial technology are available to you through various accredited online schools and colleges. Training can be completed in numerous areas and will prepare you for the exciting career you long for. Studies in this field will allow you to pursue the career that fits your individual needs and goals. Accredited online training programs can help you build the skills and knowledge needed for a successful occupation in industrial technology. Studies are available for completion from a certificate to a master degree level of education.

Career training opportunities for industrial technology are available to you through various accredited online schools and colleges. Training can be completed in numerous areas and will prepare you for the exciting career you long for. Studies in this field will allow you to pursue the career that fits your individual needs and goals. Accredited online training programs can help you build the skills and knowledge needed for a successful occupation in industrial technology. Studies are available for completion from a certificate to a master degree level of education. In today’s technology advanced society large portions of products are mass-produced for efficiency and cost. This process is used to create a wide range of products that are used in a variety of ways. The men and women who make this possible work in the field of industrial technology. Many accredited online colleges and universities offer degree distinctions in this area.

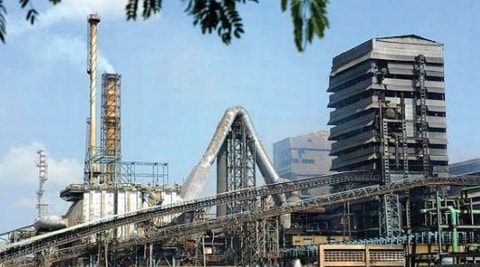

In today’s technology advanced society large portions of products are mass-produced for efficiency and cost. This process is used to create a wide range of products that are used in a variety of ways. The men and women who make this possible work in the field of industrial technology. Many accredited online colleges and universities offer degree distinctions in this area. Word Association is a fun game. Player #1 says a word – banana, for example – and Player #2 says the very first word that comes to mind – split – and so on. If I were to start this game with any given parent or teacher, it would very likely go something like this:

Word Association is a fun game. Player #1 says a word – banana, for example – and Player #2 says the very first word that comes to mind – split – and so on. If I were to start this game with any given parent or teacher, it would very likely go something like this: Metalworking has grown by leaps and bounds with the latest in manufacturing technology. Cutting tools and machining processes have evolved to the point where industrial equipment can be made faster and at lesser expense than ever before. These end products are used in every facet of life from the home to the office and in essentially every industry and market. The end result of these advances is to make the manufacturing sector competitive in the global marketplace by providing precision products at the lowest price.

Metalworking has grown by leaps and bounds with the latest in manufacturing technology. Cutting tools and machining processes have evolved to the point where industrial equipment can be made faster and at lesser expense than ever before. These end products are used in every facet of life from the home to the office and in essentially every industry and market. The end result of these advances is to make the manufacturing sector competitive in the global marketplace by providing precision products at the lowest price. Electrical maintenance presents challenges unique to the electrical contracting field. Previously, problems were mostly identified during or after an emergency, an inconvenience for the building owner that was forced to deal with an unscheduled outage.

Electrical maintenance presents challenges unique to the electrical contracting field. Previously, problems were mostly identified during or after an emergency, an inconvenience for the building owner that was forced to deal with an unscheduled outage. Metalworking has grown by leaps and bounds with the latest in manufacturing technology. Cutting tools and machining processes have evolved to the point where industrial equipment can be made faster and at lesser expense than ever before. These end products are used in every facet of life from the home to the office and in essentially every industry and market. The end result of these advances is to make the manufacturing sector competitive in the global marketplace by providing precision products at the lowest price.

Metalworking has grown by leaps and bounds with the latest in manufacturing technology. Cutting tools and machining processes have evolved to the point where industrial equipment can be made faster and at lesser expense than ever before. These end products are used in every facet of life from the home to the office and in essentially every industry and market. The end result of these advances is to make the manufacturing sector competitive in the global marketplace by providing precision products at the lowest price.