Giving Through Saving

Are you a saver? Are you a handcrafter? Do you enjoy helping others? I fall into all 3 categories which was the basis for starting my blog; Coupons, Crafts and Causes earlier this year. I wanted to educate others how easy and inexpensive it is to help others and give back no matter how much time and/or money you have. There are an endless number of non-profit organizations that are looking for items to be donated. There are several items that you throw away or recycle on a daily basis that someone within your community, our country or even our troops overseas could put to good use.

Are you a saver? Are you a handcrafter? Do you enjoy helping others? I fall into all 3 categories which was the basis for starting my blog; Coupons, Crafts and Causes earlier this year. I wanted to educate others how easy and inexpensive it is to help others and give back no matter how much time and/or money you have. There are an endless number of non-profit organizations that are looking for items to be donated. There are several items that you throw away or recycle on a daily basis that someone within your community, our country or even our troops overseas could put to good use.

One of the easiest ways to help is to save the Box Tops for Education emblems found on a select variety of General Mills products and Labels for Education emblems found on Campbell’s products (soups, Franco American, Swanson, Prego and more). Both of these can be collected and donated to a participating school. You can send them with a student or employee, drop them off at the school office or mail them in. The school earns so much per emblem submitted to use towards a variety of items for the school system. We have been saving them since both programs began. Our kids are now through school, so we save them for one of our friend’s to send with her children.

Did you know that you can donate your pop can tabs to participating McDonald’s Restaurants to benefit families of the Ronald McDonald House?

Another easy way is to donate your newspapers and magazines to a variety of different organizations. In my area, there are several local schools and churches with Newspaper Bins in their parking lot where you drop them off anytime.

I use my couponing skills to get products for free or almost free that we won’t use to donate to local food drives or pantries. Even if you aren’t an avid couponer there are ways in which you could still save and donate. For example, when your store has a Buy 1; Get 1 Free sale and you don’t need 2 of a particular item, consider donating the 2nd one. One of our local stores runs a Buy 10 participating items and get the 11th one free. If you only need 9 items, consider picking up the additional items to donate. During school supply season, consider picking up a few of the inexpensive school supplies while at the grocery, drug or office supply store and donate to a school supply drive.

Did you know that our troops can use expired manufacturer coupons? The PX and Commissaries will allow them to use expired coupons for a certain length of time. You can also send non-expired coupons as well.

I enjoy sewing, crocheting and card making. There are many organizations (non-profit and otherwise) that are in need of handmade items to donate to those in need. I’m a member of a quilt club that donates handmade quilts to those with serious illnesses, …

Whether you are just getting started welding, or you have been doing it for a while now, it is always smart to review general safety as well as the certain safety items

Whether you are just getting started welding, or you have been doing it for a while now, it is always smart to review general safety as well as the certain safety items  Welding is a process of joining materials such as metals and plastics using heat or pressure. It is the most popularly used method today to join metals, and is used extensively in the production of automobiles, ships, trains, buildings, and bridges. Compared to soldering and brazing which introduce a soft melted substance to hold original pieces together, welding process melts the metals together to form a robust and a strong join.

Welding is a process of joining materials such as metals and plastics using heat or pressure. It is the most popularly used method today to join metals, and is used extensively in the production of automobiles, ships, trains, buildings, and bridges. Compared to soldering and brazing which introduce a soft melted substance to hold original pieces together, welding process melts the metals together to form a robust and a strong join. Identifying An Instrumentation Job

Identifying An Instrumentation Job Word Association is a fun game. Player #1 says a word – banana, for example – and Player #2 says the very first word that comes to mind – split – and so on. If I were to start this game with any given parent or teacher, it would very likely go something like this:

Word Association is a fun game. Player #1 says a word – banana, for example – and Player #2 says the very first word that comes to mind – split – and so on. If I were to start this game with any given parent or teacher, it would very likely go something like this: Construction equipment is used by a variety of industries all over the world. It can include things like forklifts, excavators, steer loaders, telescopic loaders, and all terrain equipment. With so many different brands manufacturing construction

Construction equipment is used by a variety of industries all over the world. It can include things like forklifts, excavators, steer loaders, telescopic loaders, and all terrain equipment. With so many different brands manufacturing construction  Metal Inert Gas welding – better known as MIG welding- is a welding process pioneered in 1948 by the Battelle Memorial Institute, a non-profit science and development company based in Ohio, USA. Otherwise known as Gas Metal Arc Welding, the MIG technique was principally developed to weld aluminium, as well as other non-ferrous metals. MIG weldingis an automatic or semi-automatic process, which uses electrode-based welding equipment to fuse metal together. Inert gas also passes through the welding gun, acting as a shield which keeps the weld zone free of air-borne contaminants.

Metal Inert Gas welding – better known as MIG welding- is a welding process pioneered in 1948 by the Battelle Memorial Institute, a non-profit science and development company based in Ohio, USA. Otherwise known as Gas Metal Arc Welding, the MIG technique was principally developed to weld aluminium, as well as other non-ferrous metals. MIG weldingis an automatic or semi-automatic process, which uses electrode-based welding equipment to fuse metal together. Inert gas also passes through the welding gun, acting as a shield which keeps the weld zone free of air-borne contaminants. A day care center has lots and lots of supplies to cater to every child’s needs and help his/her develop all the skills necessary to grow into a mature, responsible, independent, responsive, caring, etc individual. Art equipment, toys, books and play things are among the necessary materials that help to stimulate the children’s imagination, develop and enhance their talents and skills and improve their academic performance.

A day care center has lots and lots of supplies to cater to every child’s needs and help his/her develop all the skills necessary to grow into a mature, responsible, independent, responsive, caring, etc individual. Art equipment, toys, books and play things are among the necessary materials that help to stimulate the children’s imagination, develop and enhance their talents and skills and improve their academic performance. When thinking about boat safety equipment, the first item you probably purchase is the personal flotation device, also known as the PFD. The PFD is designed to give you buoyancy in the case of an

When thinking about boat safety equipment, the first item you probably purchase is the personal flotation device, also known as the PFD. The PFD is designed to give you buoyancy in the case of an  A Daycare center is where a child gets to know more about his ABC’s and numbers and a whole lot more and you mostly teach them these things

A Daycare center is where a child gets to know more about his ABC’s and numbers and a whole lot more and you mostly teach them these things  Many people wrongly feel that protective equipment is just something that novices use. The more experienced users of chainsaws do not need them. This is totally false. Even professional loggers use protective equipment, and do so because of one reason only. It safeguards them from injuries.

Many people wrongly feel that protective equipment is just something that novices use. The more experienced users of chainsaws do not need them. This is totally false. Even professional loggers use protective equipment, and do so because of one reason only. It safeguards them from injuries. There are so many different types of cases available worldwide, all very different in size, material and purpose. A case could be something as small as a memory card case to as big as a Cello Case. They can be made from metal to cloth, a

There are so many different types of cases available worldwide, all very different in size, material and purpose. A case could be something as small as a memory card case to as big as a Cello Case. They can be made from metal to cloth, a  You know the value of an expensive car. It’s not only great to pick-up girls (or guys if you’re a gal) but it’s got all the best gizmos money can buy. Things like 55 speakers located throughout the cab of the vehicle. An umbrella holder in the door. And a full gas kitchen with a modern Danish, hardwood cutting board island.

You know the value of an expensive car. It’s not only great to pick-up girls (or guys if you’re a gal) but it’s got all the best gizmos money can buy. Things like 55 speakers located throughout the cab of the vehicle. An umbrella holder in the door. And a full gas kitchen with a modern Danish, hardwood cutting board island. One of the best ways to get great deals on communion supplies is to take your search online. If you are a church assistant and tasked to hunt down affordable communion supplies for your church, then you can go ahead and order cheap deals online.

One of the best ways to get great deals on communion supplies is to take your search online. If you are a church assistant and tasked to hunt down affordable communion supplies for your church, then you can go ahead and order cheap deals online. Having a swimming pool in your own backyard is something that you can be proud of. This is one of the great and expensive investments that

Having a swimming pool in your own backyard is something that you can be proud of. This is one of the great and expensive investments that  The hobby of candle making is enjoyable and could be sort of addictive to most because it lets you truly express your creativity by experiencing with endless ideas – from the various colors, forms of wax, scents, shapes, containers, to embellishments that are so widely available for you to play with.

The hobby of candle making is enjoyable and could be sort of addictive to most because it lets you truly express your creativity by experiencing with endless ideas – from the various colors, forms of wax, scents, shapes, containers, to embellishments that are so widely available for you to play with. It is very common for the average 21st century citizen to take even the most complex of objects and processes for granted and be completely oblivious to the goings on that don’t directly affect him or her. But half of what we do and what we’re used to wouldn’t be possible were it not for the invention of a few vital pieces of industrial equipment. Without them, manufacture on such a high level would simply not be realistic.

It is very common for the average 21st century citizen to take even the most complex of objects and processes for granted and be completely oblivious to the goings on that don’t directly affect him or her. But half of what we do and what we’re used to wouldn’t be possible were it not for the invention of a few vital pieces of industrial equipment. Without them, manufacture on such a high level would simply not be realistic. Social media has transformed the way most of the industries connect with their customers. No industry is untouched by the phenomenon. Businesses all over the world have realized the power of expression that social media provides and that it can be used as a tactical ally to connect to customers.

Social media has transformed the way most of the industries connect with their customers. No industry is untouched by the phenomenon. Businesses all over the world have realized the power of expression that social media provides and that it can be used as a tactical ally to connect to customers. New car owners are very meticulous over the way their car looks and when they start to clean, they usually consider each and every part of the car and they make sure it is flawless. But everything does fade away eventually and in the course of the next few days, your car will probably lose its shine and its colors will start to wane. Whether we like it or not, the sun and the rain will start to batter your car’s paint job and pollution in the air and dust will start to cover up the shine.

New car owners are very meticulous over the way their car looks and when they start to clean, they usually consider each and every part of the car and they make sure it is flawless. But everything does fade away eventually and in the course of the next few days, your car will probably lose its shine and its colors will start to wane. Whether we like it or not, the sun and the rain will start to batter your car’s paint job and pollution in the air and dust will start to cover up the shine. Whether you are an avid craftsmen, a DIY enthusiast or a carpenter in the trade, there are certain wood shop power tools that are necessary to support any type of job that is

Whether you are an avid craftsmen, a DIY enthusiast or a carpenter in the trade, there are certain wood shop power tools that are necessary to support any type of job that is  Picnic blankets are necessary accessories for true outdoor dining adventures. They provide a comfortable place to sit and protect your food from the ground. They also come in plenty of different designs in terms of both colors and materials. Some

Picnic blankets are necessary accessories for true outdoor dining adventures. They provide a comfortable place to sit and protect your food from the ground. They also come in plenty of different designs in terms of both colors and materials. Some  It is important to understand that incontinence is not a normal part of the aging process. However, statistics show that seniors are more at risk of developing incontinence from a variety of different factors. This makes it crucial to determine why a senior is developing incontinence if symptoms begin to

It is important to understand that incontinence is not a normal part of the aging process. However, statistics show that seniors are more at risk of developing incontinence from a variety of different factors. This makes it crucial to determine why a senior is developing incontinence if symptoms begin to  Purchasing and issuing PPE equipment is not the way to reduce the risk of injury in the workplace. Items such as safety knives and work gloves may well be designed and

Purchasing and issuing PPE equipment is not the way to reduce the risk of injury in the workplace. Items such as safety knives and work gloves may well be designed and  Safety is paramount in any woodshop, and certainly should not be overlooked when creating a woodshop at your home. Regardless of an individual’s level of experience, mistakes and accidents

Safety is paramount in any woodshop, and certainly should not be overlooked when creating a woodshop at your home. Regardless of an individual’s level of experience, mistakes and accidents  Bathroom is probably one of the most overlooked parts of the house if we’re going to talk about safety and hazards. For sure, it might appear harmless for most people especially if it’s ergonomically designed to suit our needs. However, research has consistently shown health hazards hidden within this structure and which highly deserve our full attention. In fact, studies have found out that in U.S. alone, an average of 640 people are estimated to get non-fatal to fatal bathroom-related injuries on a daily basis. And if you think this figure doesn’t encompass people of all ages, you might be missing some important health information because in reality, both children and the elderly are high-risk to get this injury. So how are we going to prevent this accident from taking place?

Bathroom is probably one of the most overlooked parts of the house if we’re going to talk about safety and hazards. For sure, it might appear harmless for most people especially if it’s ergonomically designed to suit our needs. However, research has consistently shown health hazards hidden within this structure and which highly deserve our full attention. In fact, studies have found out that in U.S. alone, an average of 640 people are estimated to get non-fatal to fatal bathroom-related injuries on a daily basis. And if you think this figure doesn’t encompass people of all ages, you might be missing some important health information because in reality, both children and the elderly are high-risk to get this injury. So how are we going to prevent this accident from taking place? When deciding whether to inspect your roof, do a repair, or walk on your roof for any other reason, there are several steps you can take to ensure your safety. These safety procedures are often overlooked, causing accidents that can affect a person and their family for years to come. However, if you invest just a small amount of time educating yourself of the potential dangers of your roof, you may avoid these incidents all together.

When deciding whether to inspect your roof, do a repair, or walk on your roof for any other reason, there are several steps you can take to ensure your safety. These safety procedures are often overlooked, causing accidents that can affect a person and their family for years to come. However, if you invest just a small amount of time educating yourself of the potential dangers of your roof, you may avoid these incidents all together. Wind turbines are springing up around the world. In fact, wind power generation is the fastest growing source of alternative energy in the world. Wind turbines are such an attractive alternative because they create no pollution, consume no fossil fuels, and are a renewable resource. Today’s technological advancements in industrial equipment, materials of construction, and tower aerodynamics continues to produce towers with greater generating capacity.

Wind turbines are springing up around the world. In fact, wind power generation is the fastest growing source of alternative energy in the world. Wind turbines are such an attractive alternative because they create no pollution, consume no fossil fuels, and are a renewable resource. Today’s technological advancements in industrial equipment, materials of construction, and tower aerodynamics continues to produce towers with greater generating capacity. When you choose a Baby Bearded Dragon, you won’t know if you’re getting a him or a her until the dragon matures. The sex of the dragon

When you choose a Baby Bearded Dragon, you won’t know if you’re getting a him or a her until the dragon matures. The sex of the dragon  Safety Equipment refers to all types of equipment which has been specifically designed to safeguard against injury and accidents either in the workplace the home or any other types of safety applications where needed.

Safety Equipment refers to all types of equipment which has been specifically designed to safeguard against injury and accidents either in the workplace the home or any other types of safety applications where needed. When you think of safety equipment and workplace safety you may think of workplaces such as factories and laboratories – the kind of environments where you’d expect to find hard hats, safety glasses and other items of vital safety equipment. What is often overlooked are the items of safety equipment and general awareness of other hazards in the workplace and this means the environments you may not expect to be fraught with danger such as an office or shop.

When you think of safety equipment and workplace safety you may think of workplaces such as factories and laboratories – the kind of environments where you’d expect to find hard hats, safety glasses and other items of vital safety equipment. What is often overlooked are the items of safety equipment and general awareness of other hazards in the workplace and this means the environments you may not expect to be fraught with danger such as an office or shop. The work horse of the uniform case sealer line-up, the Little David LD7 series has been providing significant labor savings for small to medium sized production facilities for over a decade.

The work horse of the uniform case sealer line-up, the Little David LD7 series has been providing significant labor savings for small to medium sized production facilities for over a decade. Diabetes is a disorder characterized by high amounts of sugar or glucose in the blood. It is

Diabetes is a disorder characterized by high amounts of sugar or glucose in the blood. It is  The medical supply industry is a large, growing market with a diverse manufacturing portfolio. The industry as a whole has yearly revenue of about $78 billion, mainly distributed between 60 major companies, but the total industry numbers at about 12,000 companies big and small. The products they produce satisfy the needs of hospitals, surgeons, and doctors across the world. Everything from daily disposable instruments like syringes and catheters to sutures and dressings as well as hospital beds and dental appliances are manufactured. Even latex gloves and surgical masks are produced within the industry.

The medical supply industry is a large, growing market with a diverse manufacturing portfolio. The industry as a whole has yearly revenue of about $78 billion, mainly distributed between 60 major companies, but the total industry numbers at about 12,000 companies big and small. The products they produce satisfy the needs of hospitals, surgeons, and doctors across the world. Everything from daily disposable instruments like syringes and catheters to sutures and dressings as well as hospital beds and dental appliances are manufactured. Even latex gloves and surgical masks are produced within the industry. Last week, I had to chaperone my son’s sixth-grade class on a trip to an environmental learning center. One of the activities was climbing 30 feet in the air and navigating a ropes course amongst the treetops. Finishing with a zip line was exhilarating. But before we even went up, the instructor spent a lot of time on our safety equipment. He wanted the kids to feel safe and trust their equipment so that they could forget about that part and focus on overcoming their fears. It struck me that all of us need to trust our equipment a little more in life.

Last week, I had to chaperone my son’s sixth-grade class on a trip to an environmental learning center. One of the activities was climbing 30 feet in the air and navigating a ropes course amongst the treetops. Finishing with a zip line was exhilarating. But before we even went up, the instructor spent a lot of time on our safety equipment. He wanted the kids to feel safe and trust their equipment so that they could forget about that part and focus on overcoming their fears. It struck me that all of us need to trust our equipment a little more in life. In any company, the right kind of industrial equipment is essential in ensuring a smooth, productive operation. The following lists information on industrial equipment categorized under the areas of industry they fall in:

In any company, the right kind of industrial equipment is essential in ensuring a smooth, productive operation. The following lists information on industrial equipment categorized under the areas of industry they fall in: Often times, people purchasing things like equipment for industry, are having tough times on maintaining it to be in good condition, remain functional and last long. Due to the successive use of the industrial machinery, the performance of the machines can be deteriorated and eventually results in errors and faults. In general, if the machines are not maintained and kept well, productions and other company accomplishments can be compromised and can lead to huge amounts of expenses due to the failure of operations. To avoid this from being happening, below are some of the simple DIY (Do-It-Yourself) steps on how to manage and take care of your industrial machinery:

Often times, people purchasing things like equipment for industry, are having tough times on maintaining it to be in good condition, remain functional and last long. Due to the successive use of the industrial machinery, the performance of the machines can be deteriorated and eventually results in errors and faults. In general, if the machines are not maintained and kept well, productions and other company accomplishments can be compromised and can lead to huge amounts of expenses due to the failure of operations. To avoid this from being happening, below are some of the simple DIY (Do-It-Yourself) steps on how to manage and take care of your industrial machinery: Buying new industrial equipment can be expensive. In fact, not all business owners can afford to acquire new vehicles since this can involve a considerable investment. For this reason, the market for used machinery continues to grow and develop. Furthermore, when being offered for sale at an online auction, industrial equipment can be sold fast and efficiently and is gaining popularity with buyers, sellers and manufacturers.

Buying new industrial equipment can be expensive. In fact, not all business owners can afford to acquire new vehicles since this can involve a considerable investment. For this reason, the market for used machinery continues to grow and develop. Furthermore, when being offered for sale at an online auction, industrial equipment can be sold fast and efficiently and is gaining popularity with buyers, sellers and manufacturers. Riding a motorcycle on or off-road is not an addiction, it is a way of life. Anyone that rides does it for the love of it. There is no other way to experience the freedom and the camaraderie that comes with riding. Riding also means that an understanding of basic motorcycle gear is no longer something that you have to think about. You already know.

Riding a motorcycle on or off-road is not an addiction, it is a way of life. Anyone that rides does it for the love of it. There is no other way to experience the freedom and the camaraderie that comes with riding. Riding also means that an understanding of basic motorcycle gear is no longer something that you have to think about. You already know. With the cost of electricity continually rising people are looking to ways to save on their energy consumption. There is also the need to reduce the use of electricity as it presents a strain on the environments resources and the generation of power contributes to the harmful waste being released into our atmosphere. If you can conserve the use of electrical services you can help lower electricity bills and have a positive impact on the environment.

With the cost of electricity continually rising people are looking to ways to save on their energy consumption. There is also the need to reduce the use of electricity as it presents a strain on the environments resources and the generation of power contributes to the harmful waste being released into our atmosphere. If you can conserve the use of electrical services you can help lower electricity bills and have a positive impact on the environment. What do you think of when you hear the word “warehouse supplies”? Usually, even people in the warehouse industry define the term narrowly as it applies to their business. To one company, a warehouse supply company provides packaging supplies. To another company, it supplies office products. Yet another company may think of materials handling equipment. The truth is all of these products and many more can be found in an online warehouse supply catalog.

What do you think of when you hear the word “warehouse supplies”? Usually, even people in the warehouse industry define the term narrowly as it applies to their business. To one company, a warehouse supply company provides packaging supplies. To another company, it supplies office products. Yet another company may think of materials handling equipment. The truth is all of these products and many more can be found in an online warehouse supply catalog. Today, plastic plates are usually used for large gatherings and parties, they are less expensive and more convenient. However, they have had mixed reviews since they were first introduced to the marketplace. They are typically considered to be a good substitute for traditional plates because they can be reused and they last longer than paper plates. Furthermore, these plates are highly beneficial for many reasons.

Today, plastic plates are usually used for large gatherings and parties, they are less expensive and more convenient. However, they have had mixed reviews since they were first introduced to the marketplace. They are typically considered to be a good substitute for traditional plates because they can be reused and they last longer than paper plates. Furthermore, these plates are highly beneficial for many reasons. Did you know that hundreds of thousands of people get injured at work every year? In New Zealand, for instance, the number of officially made work injury claims was 224,900 in 2008. If the workers

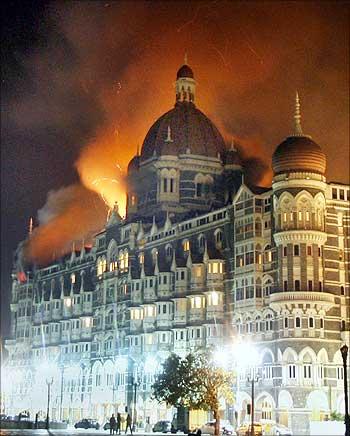

Did you know that hundreds of thousands of people get injured at work every year? In New Zealand, for instance, the number of officially made work injury claims was 224,900 in 2008. If the workers  Buying fire safety devices like a fire alarm bell is a far cry from shopping for regular things like food or clothes. When you go to the mall to shop for food items or clothing, you just go from rack to rack to see what you like and then get whatever it is that you think would be of good use to you. It is not the same thing with fire safety devices. You just cannot take a quick look and grab the first fire alarm bell you see on the store shelf. You need to spend time to learn about their features and test the quality and performance; and, of course, to find a reputable fire alarm bell supplier that will steer you towards a durable and efficient product.

Buying fire safety devices like a fire alarm bell is a far cry from shopping for regular things like food or clothes. When you go to the mall to shop for food items or clothing, you just go from rack to rack to see what you like and then get whatever it is that you think would be of good use to you. It is not the same thing with fire safety devices. You just cannot take a quick look and grab the first fire alarm bell you see on the store shelf. You need to spend time to learn about their features and test the quality and performance; and, of course, to find a reputable fire alarm bell supplier that will steer you towards a durable and efficient product.