Medical Equipment Know-How

Medical technology is that branch of medicine which deals with the technical apparatus associated with the treatment and diagnosis of diseases and medical conditions. Most hospitals and private nursing care facilities have medical equipment which consists of machines and technical devices to detect and monitor any irregularities in a patient’s medical conditions. A Biomedical Equipment Technician (BMET) is usually hired by hospital to maintain the medical equipment of medical facilities.

Medical technology is that branch of medicine which deals with the technical apparatus associated with the treatment and diagnosis of diseases and medical conditions. Most hospitals and private nursing care facilities have medical equipment which consists of machines and technical devices to detect and monitor any irregularities in a patient’s medical conditions. A Biomedical Equipment Technician (BMET) is usually hired by hospital to maintain the medical equipment of medical facilities.

Medical equipment may consist of laboratory instruments and devices to analyze the composition of urine, blood, fasces or semen. Medical monitors may be used to predict a patient’s medical state by the measurement of parameters like blood pressure, ECG, EFG as well as gases dissolved in the blood. Diagnostic equipment comprises of medical imaging machines like which are used to help diagnosis of a condition. Such devices include ultrasound, MRI and x-ray machines, and PET and CT scanners. Therapeutic apparatus consists of infusion pumps, medical lasers and LASIK surgery machines. Life support devices are used to sustain the bodily functions of the afflicted in a period of severe medical crisis. These include will consist of apparatus like the following- ventilators, anesthetic machines, heart-lung machines, ECMO, and dialysis machines.

The field of medical equipment is a rapidly advancing one and the frontiers of medical research are steadily expanding to incorporate more and more sophisticated technology. It shows tremendous scope of developing better and improved equipment maintenance cost machines to bolster healthcare and medicine as a science. The X-ray, electrocardiograph, endoscope, ultrasound scan, CT scan and the artificial heart are inventions which have revolutionized medicine quite phenomenally.

Often it is not possible under financial considerations to carry out the long- term treatment of a patient in an official medical facility like a hospital. That is when Home Medical Equipment (HME) comes into play. The patient is taken care of by a family member or any other person not a qualified medical professional in their knowledge of nursing. It is also referred to as Durable Medical Equipment or DME in medical parlance as it is designed to withstand regular and repeated use by the patient or care-giver. Common Home Medical allis chalmers pump Equipment includes easily visible and recognizable apparatuses and devices like the wheelchair, crutch, diabetic shoes, artificial limb and not so easily visible but essential aids like the nebulizer, nasal cannula, orthosis .Such devices can only be used on a doctor’s recommendation and approval and can only be purchased from a doctor’s prescription. The purchase should be carried out from a pharmacy in the vicinity to ensure 24-hour access to replacement or new purchases should the need arise in the event of an emergency.

Medical equipment supplies are governed by the field of medical logistics. It comprises of the supply and distribution of pharmaceuticals, surgical apparatus, medicines, medical equipment and other devices to doctors, nurses, technicians and laboratory analysts. Following staff costs, medical supplies are the most expensive area of the health care sector which explains the adoption of supply chain …

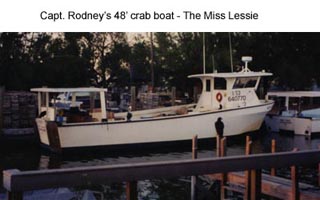

No one ever expects an accident to happen to him or her, but they do unfortunately occur. That is why every boater should

No one ever expects an accident to happen to him or her, but they do unfortunately occur. That is why every boater should .JPG/220px-BYD_Qin_(Auto_Shanghai_2013).JPG) There are many varieties of waste compaction equipment. There are large refuse, heavy duty, low emissions, drum and stationary compactors. These can have varying engine, holding and pushing capacities. Conveyors of different inclines, constructions and textures are also available.

There are many varieties of waste compaction equipment. There are large refuse, heavy duty, low emissions, drum and stationary compactors. These can have varying engine, holding and pushing capacities. Conveyors of different inclines, constructions and textures are also available. Quality industrial equipment is something every construction job should have. Considering how dangerous the work is in the first place, low quality products would only make it more risky for the people behind the scene.

Quality industrial equipment is something every construction job should have. Considering how dangerous the work is in the first place, low quality products would only make it more risky for the people behind the scene. As green technology develops and becomes more feasible by the year, it is being incorporated into business across the board, from construction to residential use. Environmentally conscious appliances, work practices, building materials, recycling and refurbishing programs, and health initiatives are steadily becoming more available and comprehensive.

As green technology develops and becomes more feasible by the year, it is being incorporated into business across the board, from construction to residential use. Environmentally conscious appliances, work practices, building materials, recycling and refurbishing programs, and health initiatives are steadily becoming more available and comprehensive. Bicycle Safety Equipment

Bicycle Safety Equipment As a mother of sons who enjoy the sport of airsoft gun wars with the use of pellets, I wanted to share with you a study done regarding eye injuries. This report/study was conducted by our friends who are ophthalmologist that specialize in retina surgery. I will attempt to paraphrase so that we laypeople might better understand their findings. Essentially the emphasis is on consistent use of protective equipment, especially goggles or full facemasks.

As a mother of sons who enjoy the sport of airsoft gun wars with the use of pellets, I wanted to share with you a study done regarding eye injuries. This report/study was conducted by our friends who are ophthalmologist that specialize in retina surgery. I will attempt to paraphrase so that we laypeople might better understand their findings. Essentially the emphasis is on consistent use of protective equipment, especially goggles or full facemasks. In getting started with an industrial business what you should best be prepared for is the expensive cost of good equipment for industry. It is very important that you purchase the best equipment to use for your business because the outcomes of your products greatly depend on them and it will also most likely determine the profit that you will be getting from your business.

In getting started with an industrial business what you should best be prepared for is the expensive cost of good equipment for industry. It is very important that you purchase the best equipment to use for your business because the outcomes of your products greatly depend on them and it will also most likely determine the profit that you will be getting from your business. As safety regulations and standards have improved over the years, employers have been more effective at supplying the proper safety equipment needed by employees to protect themselves. Similarly, employees have developed better habits with regards to wearing and using the proper safety equipment in their daily work routine. On occasion, this progression towards higher safety standards has surfaced the question of who should pay for the safety supplies. Historically, many OSHA standards and regulations required that the employer provide the employees with protective equipment when such equipment was necessary to protect employees from job-related injuries or illnesses. These requirements included the standard safety products such as hard hats, safety glasses, gloves, respiratory protection, protective clothing, and fall protection equipment. However, some of these provisions did not make it clear that the employer should pay for the cost of providing all safety items.

As safety regulations and standards have improved over the years, employers have been more effective at supplying the proper safety equipment needed by employees to protect themselves. Similarly, employees have developed better habits with regards to wearing and using the proper safety equipment in their daily work routine. On occasion, this progression towards higher safety standards has surfaced the question of who should pay for the safety supplies. Historically, many OSHA standards and regulations required that the employer provide the employees with protective equipment when such equipment was necessary to protect employees from job-related injuries or illnesses. These requirements included the standard safety products such as hard hats, safety glasses, gloves, respiratory protection, protective clothing, and fall protection equipment. However, some of these provisions did not make it clear that the employer should pay for the cost of providing all safety items. Used in industrial controls, robotics, and other electro-mechanical devices, a rotary encoder or shaft encoders are responsible for converting the angle at which a shaft is positioned into digital code which computers understand. This makes industrial devices perform more precise operations. Examples of these industrial devices would be flood gates, telescopes, and many more.

Used in industrial controls, robotics, and other electro-mechanical devices, a rotary encoder or shaft encoders are responsible for converting the angle at which a shaft is positioned into digital code which computers understand. This makes industrial devices perform more precise operations. Examples of these industrial devices would be flood gates, telescopes, and many more. Springs are an important tooling component for providing tension and are an all around useful example of industrial equipment supplies. However, those little metal coils can be impractical to work with due to their small size, fragility, and tendency to slip out of the hand when under tension.

Springs are an important tooling component for providing tension and are an all around useful example of industrial equipment supplies. However, those little metal coils can be impractical to work with due to their small size, fragility, and tendency to slip out of the hand when under tension. Replacement parts for sand mixers are important part of foundry equipments. The mixing machines are exposed to a lot of wear and tear and looking for best maintenance options is quite a practical thing to do. Buying new mixers is not possible always because of the cost factor involved. Moreover, it is not an intelligent approach to waste away the whole equipment when few replacements can make up for the damage. Proper functioning is the only expectation from the mixing machines and thus some vendors make money by simply providing replacement parts for the machines that are instrumental in the making of a huge building.

Replacement parts for sand mixers are important part of foundry equipments. The mixing machines are exposed to a lot of wear and tear and looking for best maintenance options is quite a practical thing to do. Buying new mixers is not possible always because of the cost factor involved. Moreover, it is not an intelligent approach to waste away the whole equipment when few replacements can make up for the damage. Proper functioning is the only expectation from the mixing machines and thus some vendors make money by simply providing replacement parts for the machines that are instrumental in the making of a huge building. When it comes to baby safety equipment there are many things that come into play such as safety gates, outlet covers, door locks, and even toilet covers. The reason you want to get as much baby safety equipment as possible is so you can do everything in your power to keep your child safe and out of harms way.

When it comes to baby safety equipment there are many things that come into play such as safety gates, outlet covers, door locks, and even toilet covers. The reason you want to get as much baby safety equipment as possible is so you can do everything in your power to keep your child safe and out of harms way. Because you own a swimming pool or wish to own one, there are plenty of precautions you’re going to need to know and understand in order to keep pool side accidents from occurring around your home. Some of the pool safety equipment tools mentioned here are items required by law in most states, but even if they’re not you should consider having these safety tools around so your swimming pool is safer.

Because you own a swimming pool or wish to own one, there are plenty of precautions you’re going to need to know and understand in order to keep pool side accidents from occurring around your home. Some of the pool safety equipment tools mentioned here are items required by law in most states, but even if they’re not you should consider having these safety tools around so your swimming pool is safer. Welding is a progression using heat or pressure to join mutually materials such as metal or synthetic. Welding Equipment is a ordinary

Welding is a progression using heat or pressure to join mutually materials such as metal or synthetic. Welding Equipment is a ordinary  Operating a warehouse can be a tedious task without the correct industrial supplies and in particular, the correct handling equipment to move around the materials and stock in your business storage facility.

Operating a warehouse can be a tedious task without the correct industrial supplies and in particular, the correct handling equipment to move around the materials and stock in your business storage facility. There is great interest in the global community about the worldwide reach of an auction. Bidding facilities are a strategic avenue to auction industrial equipment by being open to the public, allowing a large number of buyers to bid on vehicles with an equal chance of purchasing such equipment.

There is great interest in the global community about the worldwide reach of an auction. Bidding facilities are a strategic avenue to auction industrial equipment by being open to the public, allowing a large number of buyers to bid on vehicles with an equal chance of purchasing such equipment. In these uncertain economic times, companies have had to make many difficult decisions to keep functioning. Automotive and industrial companies have been hit particularly hard by the recession

In these uncertain economic times, companies have had to make many difficult decisions to keep functioning. Automotive and industrial companies have been hit particularly hard by the recession  When nations start to get industrialized, several companies tried to enter the scene. More and more countries sought high quality industrial equipment. Without a doubt, high end equipments are needed for a wide range of industrial processes. We won’t come up with all the products and services that we enjoy today without these.

When nations start to get industrialized, several companies tried to enter the scene. More and more countries sought high quality industrial equipment. Without a doubt, high end equipments are needed for a wide range of industrial processes. We won’t come up with all the products and services that we enjoy today without these. No company could be run without appropriate industrial equipment. Whenever an entrepreneur thinks of launching a new project, their first thought regarding their project would be to arrange the necessary industrial equipment for the project. Nowadays, with the development of technology, people are becoming much more interested about launching new commercial businesses. Therefore, the demand of industrial equipment is increasing rapidly. Commercial industries can be very important for the development of a country’s economy. With proper monitoring of various industries, any country could become self-contained as they would then be able to earn a stable income by exporting the product to other counties in the world. Thus, the improvement of modern industries may be able to help a country to have a strong economy.

No company could be run without appropriate industrial equipment. Whenever an entrepreneur thinks of launching a new project, their first thought regarding their project would be to arrange the necessary industrial equipment for the project. Nowadays, with the development of technology, people are becoming much more interested about launching new commercial businesses. Therefore, the demand of industrial equipment is increasing rapidly. Commercial industries can be very important for the development of a country’s economy. With proper monitoring of various industries, any country could become self-contained as they would then be able to earn a stable income by exporting the product to other counties in the world. Thus, the improvement of modern industries may be able to help a country to have a strong economy. Dentists make a large investment in their practice to be seen as credible health care providers and a large part of this is in dental supplies and dental materials. Running a practice is not easy or cheap and while certain costs cannot be avoided, purchasing via online dental suppliers can certainly result in savings.

Dentists make a large investment in their practice to be seen as credible health care providers and a large part of this is in dental supplies and dental materials. Running a practice is not easy or cheap and while certain costs cannot be avoided, purchasing via online dental suppliers can certainly result in savings. Fires are known to cause loss of not only property, but life also. They become uncontrollable easily and you need to be prepared to protect yourself if you are ever caught in a fire.

Fires are known to cause loss of not only property, but life also. They become uncontrollable easily and you need to be prepared to protect yourself if you are ever caught in a fire. One of the best industrial equipment tips is to be safe. The safety of industrial machinery mostly lies on a well functioning and operating one. Aside from moving vehicles, technologically advanced factories have powerful machines that are stationary like grinders, drills, sanders and Stampers and many more. The knowledge in using and handling these machinery is one thing; the knowledge of its hazards, risks and safety precautions is another. These are two sets of

One of the best industrial equipment tips is to be safe. The safety of industrial machinery mostly lies on a well functioning and operating one. Aside from moving vehicles, technologically advanced factories have powerful machines that are stationary like grinders, drills, sanders and Stampers and many more. The knowledge in using and handling these machinery is one thing; the knowledge of its hazards, risks and safety precautions is another. These are two sets of  For generations, the automobile’s only real safety equipment were the brakes. Cars were enormous inflexible boats made of steel with bench seats and not much else. But since the seat belt was first introduced as a standard feature in the late 1950s, both manufacturers and consumers have been taking a larger interest in the safety features of the automobile. Consumers are interested in buying the safest vehicle on the market – whether for real or perceived qualities. Crash testing and accident reports have become a major selling point for automobiles.

For generations, the automobile’s only real safety equipment were the brakes. Cars were enormous inflexible boats made of steel with bench seats and not much else. But since the seat belt was first introduced as a standard feature in the late 1950s, both manufacturers and consumers have been taking a larger interest in the safety features of the automobile. Consumers are interested in buying the safest vehicle on the market – whether for real or perceived qualities. Crash testing and accident reports have become a major selling point for automobiles. Plasma cutting is a fast growing method that is considered as one among the fantastic technologies nowadays. It’s powerful in whatever ways we want it to be. Heated up as well as commanding characteristic features

Plasma cutting is a fast growing method that is considered as one among the fantastic technologies nowadays. It’s powerful in whatever ways we want it to be. Heated up as well as commanding characteristic features