Pool Safety Measures

Water can be a child’s best friend. It’s fun, cool to the touch, and children can play in it for hours and never get bored. But it can also be deadly. Horror stories about the consequences of leaving a child unattended at the pool pervade the Internet and the news. Taking the proper safety measures can prevent a tragedy and keep the pool a fun place for all.

Water can be a child’s best friend. It’s fun, cool to the touch, and children can play in it for hours and never get bored. But it can also be deadly. Horror stories about the consequences of leaving a child unattended at the pool pervade the Internet and the news. Taking the proper safety measures can prevent a tragedy and keep the pool a fun place for all.

You should always have a lot of safety equipment around the pool. You never know what you machinery and equipment examples may need or when you may need it, so it is always best to be prepared for anything.

A shepherd’s hook is a good safety device to have around. It can be used to remove a drowning person from the pool, saving you the potentially dangerous trouble of entering the pool yourself to save them. Drown victims have been known to lock their arms around their rescuers, impairing the rescuer’s ability to swim and effectively killing them both. Another useful device is one that greatly assists anyone in an emergency of any kind: a phone. Being able to call for help is important, should the situation escalate beyond your capabilities.

Protecting your pool with a strong fence is another effective safety measure. It keeps your children from entering the pool without your knowledge and allows you to control who can get into your pool.

Fences have to be tall enough to discourage climbing. Nothing less than 6 feet should be used, and the fence should be able to be locked. Keep the key in a safe place and no one will be getting in unless you let them.

Knowing how to perform CPR makes you an asset in any emergency life or death situation, and makes anywhere you are a much safer place. If someone needs to be revived by CPR, you will have the ability to save them.

Be sure to keep an eye on people who can’t swim when they get into or around your pool. You never want to consider yourself over prepared in this regard, as people who aren’t used to being around water shouldn’t be around it. Such individuals are more prone to disaster since they cannot take care of themselves should a situation arise.

Pools should be places of safe, family fun. Know your safety rules and prepare yourself for the worst; only industrial machinery suppliers then can you relax in the knowledge that your loved ones are safe and you are ready for whatever happens.…

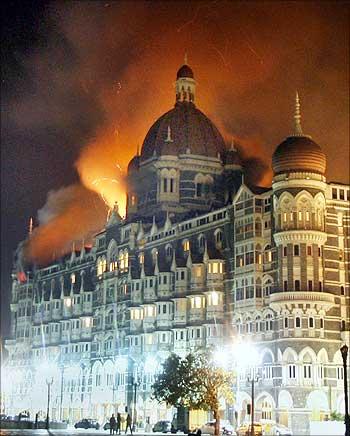

Fire safety equipment is one aspect of fire prevention that should be prioritized by many homeowners, building proprietors and business holders. There is a wide array of fire safety devices offered in this present day and age. One such reliable

Fire safety equipment is one aspect of fire prevention that should be prioritized by many homeowners, building proprietors and business holders. There is a wide array of fire safety devices offered in this present day and age. One such reliable  Fire fighting equipment protects people and businesses during fire accidents. It keeps people safe wherever they live and work. Regular inspection and servicing of the equipment meant for the safety of the occupants to the relevant standards is very crucial. Daily, weekly, monthly, quarterly and annual inspections are done to ensure the equipment’s functionality, and maintain all other aspects of fire safety management.

Fire fighting equipment protects people and businesses during fire accidents. It keeps people safe wherever they live and work. Regular inspection and servicing of the equipment meant for the safety of the occupants to the relevant standards is very crucial. Daily, weekly, monthly, quarterly and annual inspections are done to ensure the equipment’s functionality, and maintain all other aspects of fire safety management. Growing a baby at home is a task which should be given a lot of importance as they are prone to a lot of serious hazards. As a growing child they have the urge for exploring their surroundings. When

Growing a baby at home is a task which should be given a lot of importance as they are prone to a lot of serious hazards. As a growing child they have the urge for exploring their surroundings. When  It is true that enjoying a swimming pool is one of the summer’s favorite time pass. Both adults as well as kids enjoy time at pools and it is one of those activities, which give family-fun options. Nevertheless, there are many potential hazards associated with swimming pools and one must take precautionary measures to ensure nothing unbearable happens to your lovely kids. Some of the potential pool hazards for children includes following:

It is true that enjoying a swimming pool is one of the summer’s favorite time pass. Both adults as well as kids enjoy time at pools and it is one of those activities, which give family-fun options. Nevertheless, there are many potential hazards associated with swimming pools and one must take precautionary measures to ensure nothing unbearable happens to your lovely kids. Some of the potential pool hazards for children includes following: A shower enclosure is one of the most important investments that every home owner has to make. Therefore you have to be very careful about the type of unit you invest in. It is rather expensive to keep replacing your bathroom enclosures with new ones every so often. Therefore before you decide to buy any of the available tubs, it is appropriate to research widely and gather enough details about the best tubs. Luckily, there are numerous sources of information that can give you reliable details about the best enclosures. You can even do a thorough online research on these units. However, ensure that you get your material from a reliable bathroom blog.

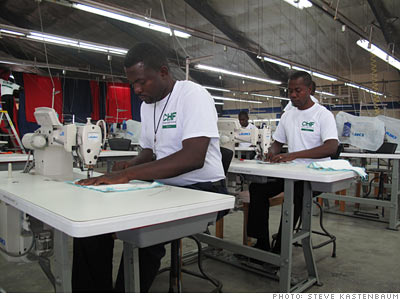

A shower enclosure is one of the most important investments that every home owner has to make. Therefore you have to be very careful about the type of unit you invest in. It is rather expensive to keep replacing your bathroom enclosures with new ones every so often. Therefore before you decide to buy any of the available tubs, it is appropriate to research widely and gather enough details about the best tubs. Luckily, there are numerous sources of information that can give you reliable details about the best enclosures. You can even do a thorough online research on these units. However, ensure that you get your material from a reliable bathroom blog. Metalworking has grown by leaps and bounds with the latest in manufacturing technology. Cutting tools and machining processes have evolved to the point where industrial equipment can be made faster and at lesser expense than ever before. These end products are used in every facet of life from the home to the office and in essentially every industry and market. The end result of these advances is to make the manufacturing sector competitive in the global marketplace by providing precision products at the lowest price.

Metalworking has grown by leaps and bounds with the latest in manufacturing technology. Cutting tools and machining processes have evolved to the point where industrial equipment can be made faster and at lesser expense than ever before. These end products are used in every facet of life from the home to the office and in essentially every industry and market. The end result of these advances is to make the manufacturing sector competitive in the global marketplace by providing precision products at the lowest price. If you have children and a swimming pool you know that safety is an important issue. You should never leave your children alone near the pool. Kids love water and even the most obedient child can give in to temptation and jump in if you’re not around. This can be dangerous because they can get a cramp or hit their head and if you’re not there to save them, they could drown. If you have to leave the pool area, take your children with you.

If you have children and a swimming pool you know that safety is an important issue. You should never leave your children alone near the pool. Kids love water and even the most obedient child can give in to temptation and jump in if you’re not around. This can be dangerous because they can get a cramp or hit their head and if you’re not there to save them, they could drown. If you have to leave the pool area, take your children with you. New car owners are very meticulous over the way their car looks and when they start to clean, they usually consider each and every part of the car and they make sure it is flawless. But everything does fade away eventually and in the course of the next few days, your car will probably lose its shine and its colors will start to wane. Whether we like it or not, the sun and the rain will start to batter your car’s paint job and pollution in the air and dust will start to cover up the shine.

New car owners are very meticulous over the way their car looks and when they start to clean, they usually consider each and every part of the car and they make sure it is flawless. But everything does fade away eventually and in the course of the next few days, your car will probably lose its shine and its colors will start to wane. Whether we like it or not, the sun and the rain will start to batter your car’s paint job and pollution in the air and dust will start to cover up the shine. Workholding is an often overlooked part of machine work. Typically, operators and workers put materials into some type of industrial equipment for stability and hold. However, the right hold is absolutely vital for precision and safety. If materials slip during a machine process, there are more consequences than just an off specification product. Ultimately, when workholding fails, it is not uncommon for machines to become damaged and injuries to occur to operators. This is why it is vital to examine and understand the different types of workholding industrial equipment and their applications.

Workholding is an often overlooked part of machine work. Typically, operators and workers put materials into some type of industrial equipment for stability and hold. However, the right hold is absolutely vital for precision and safety. If materials slip during a machine process, there are more consequences than just an off specification product. Ultimately, when workholding fails, it is not uncommon for machines to become damaged and injuries to occur to operators. This is why it is vital to examine and understand the different types of workholding industrial equipment and their applications. Industrial workers must have these in order to protect themselves: eye protection; hearing protection; helmets, boots, and gloves; fire protection; and respirators.

Industrial workers must have these in order to protect themselves: eye protection; hearing protection; helmets, boots, and gloves; fire protection; and respirators. What is an Equipment Lease Agreement?

What is an Equipment Lease Agreement? Every worksite needs to be clean and orderly in order to function safely and productively. Sanitation is especially important in the food product manufacturing industry. Federal laws and standards are explicit and stringent in mandating how food products are manufactured with specifications on industrial equipment and industrial supplies used in this industry. When it comes to producing foodstuffs, any contamination from bacteria or even dirt can cause health problems for end consumers.

Every worksite needs to be clean and orderly in order to function safely and productively. Sanitation is especially important in the food product manufacturing industry. Federal laws and standards are explicit and stringent in mandating how food products are manufactured with specifications on industrial equipment and industrial supplies used in this industry. When it comes to producing foodstuffs, any contamination from bacteria or even dirt can cause health problems for end consumers. Whether you are an avid craftsmen, a DIY enthusiast or a carpenter in the trade, there are certain wood shop power tools that are necessary to support any type of job that is

Whether you are an avid craftsmen, a DIY enthusiast or a carpenter in the trade, there are certain wood shop power tools that are necessary to support any type of job that is  Motorcycle Racing is an exciting, physically demanding hobby that can be extremely rewarding, as long as it’s practiced with safety in mind. The most important things to consider when you’re thinking about attending your first track meet or racing event is to be sure that you have taken the proper steps to ensure your safety and the safety of those around you.

Motorcycle Racing is an exciting, physically demanding hobby that can be extremely rewarding, as long as it’s practiced with safety in mind. The most important things to consider when you’re thinking about attending your first track meet or racing event is to be sure that you have taken the proper steps to ensure your safety and the safety of those around you. Picnic blankets are necessary accessories for true outdoor dining adventures. They provide a comfortable place to sit and protect your food from the ground. They also come in plenty of different designs in terms of both colors and materials. Some

Picnic blankets are necessary accessories for true outdoor dining adventures. They provide a comfortable place to sit and protect your food from the ground. They also come in plenty of different designs in terms of both colors and materials. Some  There comes a time when standard industrial products do not fit the needs for manufacturing. Whether custom sizes or materials or even entirely reworked industrial equipment are required, most companies will find themselves in the position that they need to order the fabrication of industrial products. There are many factors to consider when shopping for unique equipment solutions, and we will take the time to touch on them in this article.

There comes a time when standard industrial products do not fit the needs for manufacturing. Whether custom sizes or materials or even entirely reworked industrial equipment are required, most companies will find themselves in the position that they need to order the fabrication of industrial products. There are many factors to consider when shopping for unique equipment solutions, and we will take the time to touch on them in this article. There’s no denying that pool party ideas can be great fun, particularly during the hot summer months. Your children can enjoy splashing around in the pool with their friends while you and the other parents have fun of your own kind. Having a kids pool party can be a lot like a beach vacation without

There’s no denying that pool party ideas can be great fun, particularly during the hot summer months. Your children can enjoy splashing around in the pool with their friends while you and the other parents have fun of your own kind. Having a kids pool party can be a lot like a beach vacation without  Balloons are universally adored. All age group individuals love them in birth anniversary celebrations. Balloons are versatile decor items- they add colour and zest to the party and if used sensibly, double up as creative artwork.

Balloons are universally adored. All age group individuals love them in birth anniversary celebrations. Balloons are versatile decor items- they add colour and zest to the party and if used sensibly, double up as creative artwork. Industrial apparel is more than just a fashion statement; wearing the right clothing on the job site is an essential component of effective personal protective equipment, or PPE. Effective PPE is designed to mitigate workplace hazards and the clothing that workers wear contributes to their own safety on the job. The right industrial apparel and products are essential for effective PPE that meets federal safety guidelines and standards as well.

Industrial apparel is more than just a fashion statement; wearing the right clothing on the job site is an essential component of effective personal protective equipment, or PPE. Effective PPE is designed to mitigate workplace hazards and the clothing that workers wear contributes to their own safety on the job. The right industrial apparel and products are essential for effective PPE that meets federal safety guidelines and standards as well. Many states require you to have all basic equipment on board before going boating. If you fail to do so, you may be fined heavily. However, the fines are not the only motivation for carrying boating

Many states require you to have all basic equipment on board before going boating. If you fail to do so, you may be fined heavily. However, the fines are not the only motivation for carrying boating  People who keep pets absolutely love and adore them, especially those who have feathered pets. You might feed your bird regularly, play with it, make it sing; make it speak but have you ever thought about how comfortable the bird is inside its cage? The cage to a bird is like a house to your average human. The fact that the bird is not going to be let out of the cage makes it all the more important for us to choose the right and comfortable cage for the birds.

People who keep pets absolutely love and adore them, especially those who have feathered pets. You might feed your bird regularly, play with it, make it sing; make it speak but have you ever thought about how comfortable the bird is inside its cage? The cage to a bird is like a house to your average human. The fact that the bird is not going to be let out of the cage makes it all the more important for us to choose the right and comfortable cage for the birds. Every worksite needs to be clean and orderly in order to function safely and productively. Sanitation is especially important in the food product manufacturing industry. Federal laws and standards are explicit and stringent in mandating how food products are manufactured with specifications on industrial equipment and industrial supplies used in this industry. When it comes to producing foodstuffs, any contamination from bacteria or even dirt can cause health problems for end consumers.

Every worksite needs to be clean and orderly in order to function safely and productively. Sanitation is especially important in the food product manufacturing industry. Federal laws and standards are explicit and stringent in mandating how food products are manufactured with specifications on industrial equipment and industrial supplies used in this industry. When it comes to producing foodstuffs, any contamination from bacteria or even dirt can cause health problems for end consumers. It is important to understand that incontinence is not a normal part of the aging process. However, statistics show that seniors are more at risk of developing incontinence from a variety of different factors. This makes it crucial to determine why a senior is developing incontinence if symptoms begin to

It is important to understand that incontinence is not a normal part of the aging process. However, statistics show that seniors are more at risk of developing incontinence from a variety of different factors. This makes it crucial to determine why a senior is developing incontinence if symptoms begin to  Welding is a manufacturing process that is used extensively in equipment manufacturing. Welding involves applying heat and flux to 2 metal pieces and fusing them together into one single homogenous joint. Welding can be MIG or TIG and performed manually or robotically. There are many parts, both in equipment and consumables, that are required to perform a welding operation. Weld gas is one such welding supply. A high voltage power supply is also required to provide the electrical energy required to produce the weld arc needed to melt the material.

Welding is a manufacturing process that is used extensively in equipment manufacturing. Welding involves applying heat and flux to 2 metal pieces and fusing them together into one single homogenous joint. Welding can be MIG or TIG and performed manually or robotically. There are many parts, both in equipment and consumables, that are required to perform a welding operation. Weld gas is one such welding supply. A high voltage power supply is also required to provide the electrical energy required to produce the weld arc needed to melt the material. Disposable medical supplies are the result of infection control’s efforts in hospitals and other healthcare establishments to ensure staff and patient safety. Stopping infections and cross-contamination caused by treatment in a hospital or other healthcare unit with the use of disposable items used for testing and treatment is the best answer for safety. Infections pose a serious health risk for patients and medical professionals alike, so the best solution for sterilization is the concept of single-use items. The Center for Disease Control and Prevention (CDCP) estimate that there are nearly 100,000 deaths in the United States every year which can be connected to about 1.7 million hospital-associated infections. All in the medical field, doctors, dentists, care givers, EMTs and etc. have been looking for ways to diminish these numbers, and disposable medical supplies are a key element in accomplishing this goal. What else has been in use?

Disposable medical supplies are the result of infection control’s efforts in hospitals and other healthcare establishments to ensure staff and patient safety. Stopping infections and cross-contamination caused by treatment in a hospital or other healthcare unit with the use of disposable items used for testing and treatment is the best answer for safety. Infections pose a serious health risk for patients and medical professionals alike, so the best solution for sterilization is the concept of single-use items. The Center for Disease Control and Prevention (CDCP) estimate that there are nearly 100,000 deaths in the United States every year which can be connected to about 1.7 million hospital-associated infections. All in the medical field, doctors, dentists, care givers, EMTs and etc. have been looking for ways to diminish these numbers, and disposable medical supplies are a key element in accomplishing this goal. What else has been in use? Our fathers always taught us to use the right tool for the right job, which still works today, especially in industry. The right industrial supplies make all the difference between running an operation and being a truly efficient business.

Our fathers always taught us to use the right tool for the right job, which still works today, especially in industry. The right industrial supplies make all the difference between running an operation and being a truly efficient business. Often times, people purchasing things like equipment for industry, are having tough times on maintaining it to be in good condition, remain functional and last long. Due to the successive use of the industrial machinery, the performance of the machines can be deteriorated and eventually results in errors and faults. In general, if the machines are not maintained and kept well, productions and other company accomplishments can be compromised and can lead to huge amounts of expenses due to the failure of operations. To avoid this from being happening, below are some of the simple DIY (Do-It-Yourself) steps on how to manage and take care of your industrial machinery:

Often times, people purchasing things like equipment for industry, are having tough times on maintaining it to be in good condition, remain functional and last long. Due to the successive use of the industrial machinery, the performance of the machines can be deteriorated and eventually results in errors and faults. In general, if the machines are not maintained and kept well, productions and other company accomplishments can be compromised and can lead to huge amounts of expenses due to the failure of operations. To avoid this from being happening, below are some of the simple DIY (Do-It-Yourself) steps on how to manage and take care of your industrial machinery: In today’s fast-paced world, the sky’s the limit for a lot of the modern office buildings that are on the rise. As corporations build to stratospheric levels, more and more

In today’s fast-paced world, the sky’s the limit for a lot of the modern office buildings that are on the rise. As corporations build to stratospheric levels, more and more  I was watching Jessica Simpson on the Oprah Winfrey show recently. Jessica Simpson’s career started as a squeaky clean character, but wealth and celebrity boosted her into the lime light and the scrutiny of everyone. The snappers are every where she is going, and there relentless pursuits have taken away her freedoms and her capabilities to live a regular life.

I was watching Jessica Simpson on the Oprah Winfrey show recently. Jessica Simpson’s career started as a squeaky clean character, but wealth and celebrity boosted her into the lime light and the scrutiny of everyone. The snappers are every where she is going, and there relentless pursuits have taken away her freedoms and her capabilities to live a regular life. There is nothing worse than being stuck in the dark without a light source. Everyone should be prepared with a flashlight in general in case of emergency. For those that are looking for professional use of their flashlight, there are a lot of useful options to choose from. Here are some of the features you are looking at when investing in a professional flashlight for your home or work zone.

There is nothing worse than being stuck in the dark without a light source. Everyone should be prepared with a flashlight in general in case of emergency. For those that are looking for professional use of their flashlight, there are a lot of useful options to choose from. Here are some of the features you are looking at when investing in a professional flashlight for your home or work zone. Sports are fun to watch and to play, as long as the spirit of sport and the rules of the particular sport are adhered to. To be successful at any sport, you have to develop the discipline and single mindedness that will lead to winning. However, at no time should a “win at all costs” mentality be considered.

Sports are fun to watch and to play, as long as the spirit of sport and the rules of the particular sport are adhered to. To be successful at any sport, you have to develop the discipline and single mindedness that will lead to winning. However, at no time should a “win at all costs” mentality be considered. Are you in need of a small lightweight torch for jewelry or other small items? Then the Smith Little Torch is your best solution. The Little Torch works exceptionally well for materials ranging from 3/16″ to especially small wires. This Tiny Torch welds, brazes, heats and solders most small projects and is equipped with 5 tips with more available.

Are you in need of a small lightweight torch for jewelry or other small items? Then the Smith Little Torch is your best solution. The Little Torch works exceptionally well for materials ranging from 3/16″ to especially small wires. This Tiny Torch welds, brazes, heats and solders most small projects and is equipped with 5 tips with more available. If you’re thinking of solar power as an option for your home, then congratulations. Taking steps towards renewable energy is a worthy cause. There are many options with solar electricity in terms of how much you want to use, how you want to combine it with other sources and installation options. Solar power is expensive to install in homes and offices and must be done by an electrician, but once installed, there is only the negligible cost of maintenance to worry about, and the savings attached with the use of this power source. It’s worthwhile thinking about the energy that you use and whether solar power can realistically meet your demand.

If you’re thinking of solar power as an option for your home, then congratulations. Taking steps towards renewable energy is a worthy cause. There are many options with solar electricity in terms of how much you want to use, how you want to combine it with other sources and installation options. Solar power is expensive to install in homes and offices and must be done by an electrician, but once installed, there is only the negligible cost of maintenance to worry about, and the savings attached with the use of this power source. It’s worthwhile thinking about the energy that you use and whether solar power can realistically meet your demand. It never fails- you’re knee deep in plastic goo and the “Injection molding machines fault” light comes on, bringing the entire operation to a crash halt. You tell the men to take five and hit the candy machine, but getting it back on board can mean hours and headaches, or it might just mean a quick flip of a switch. Like your vehicle’s check engine light, it’s a notification that can spell calamity or a minor problem. Knowing the difference can save you the price of the mechanic when you know how to fix it yourself. On the other hand, the sooner you know the machine is cooked, the sooner you can start hitting the equipment auctions for a replacement.

It never fails- you’re knee deep in plastic goo and the “Injection molding machines fault” light comes on, bringing the entire operation to a crash halt. You tell the men to take five and hit the candy machine, but getting it back on board can mean hours and headaches, or it might just mean a quick flip of a switch. Like your vehicle’s check engine light, it’s a notification that can spell calamity or a minor problem. Knowing the difference can save you the price of the mechanic when you know how to fix it yourself. On the other hand, the sooner you know the machine is cooked, the sooner you can start hitting the equipment auctions for a replacement. Heat exchangers are used in a variety of industrial processes. More specifically products built by Alfa Laval are used for heating, cooling, separating and transporting products/fluids from one medium to another.

Heat exchangers are used in a variety of industrial processes. More specifically products built by Alfa Laval are used for heating, cooling, separating and transporting products/fluids from one medium to another. If you’re an employer and your staff are engaged in any work activities that may represent any level of danger to their health or safety, you’re required, under UK law, to provide adequate PPE. PPE stands for Personal Protective Equipment and is given to members of your workforce in order to protect them from potential harm where other measures are not able to negate these possible risks.

If you’re an employer and your staff are engaged in any work activities that may represent any level of danger to their health or safety, you’re required, under UK law, to provide adequate PPE. PPE stands for Personal Protective Equipment and is given to members of your workforce in order to protect them from potential harm where other measures are not able to negate these possible risks. Nowadays, it is very unusual to find only one parent pursuing a career. More often than not, mother and father both have steady jobs, are both trying to climb up the corporate ladder, and both are trying to contribute to the family’s future.

Nowadays, it is very unusual to find only one parent pursuing a career. More often than not, mother and father both have steady jobs, are both trying to climb up the corporate ladder, and both are trying to contribute to the family’s future. MIG welding is one of the simplest ways of welding, but it does need a good practice to perform such kind of welding. With the perfect tool and the requisite experience you could carry out the best quality welds with the help of MIG welding machines.

MIG welding is one of the simplest ways of welding, but it does need a good practice to perform such kind of welding. With the perfect tool and the requisite experience you could carry out the best quality welds with the help of MIG welding machines. Manufacturers choose to use and maintain old equipment over purchasing new equipment for several reasons, but the biggest one is that older machines work, and work well. Older industrial equipment is expensive to run and work with, but it can also require a significant investment to replace. The other problem is that sometimes the new machines simply don’t produce consistent, high quality results like older ones do.

Manufacturers choose to use and maintain old equipment over purchasing new equipment for several reasons, but the biggest one is that older machines work, and work well. Older industrial equipment is expensive to run and work with, but it can also require a significant investment to replace. The other problem is that sometimes the new machines simply don’t produce consistent, high quality results like older ones do. There are ride on toys suitable for all ages from tiny tots aged 12 months to children 12 and older! Rocking horses, balance bikes and electric scooters all fit into the ride on toy family and the only supplementary thing required with ride-on toys are optional helmets and protective knee and elbow pads.

There are ride on toys suitable for all ages from tiny tots aged 12 months to children 12 and older! Rocking horses, balance bikes and electric scooters all fit into the ride on toy family and the only supplementary thing required with ride-on toys are optional helmets and protective knee and elbow pads. Purchasing and issuing PPE equipment is not the way to reduce the risk of injury in the workplace. Items such as safety knives and work gloves may well be designed and

Purchasing and issuing PPE equipment is not the way to reduce the risk of injury in the workplace. Items such as safety knives and work gloves may well be designed and  1. Use long life fluorescent bulbs and lamps. Long life fluorescent lamps require

1. Use long life fluorescent bulbs and lamps. Long life fluorescent lamps require  Industrial equipment auctions often play an important part in today’s business world and can be a lucrative way for both buyers and sellers to conduct business. It may be critical for some companies trying to keep their heads above water in tough financial times to quickly sell a vehicle no longer needed to obtain operating money. Then another company may need to purchase a high-quality, used vehicle to replace a non-working one to stay in business. Whatever the case may be, a modern-day bidding experience can be very different from what may be envisioned.

Industrial equipment auctions often play an important part in today’s business world and can be a lucrative way for both buyers and sellers to conduct business. It may be critical for some companies trying to keep their heads above water in tough financial times to quickly sell a vehicle no longer needed to obtain operating money. Then another company may need to purchase a high-quality, used vehicle to replace a non-working one to stay in business. Whatever the case may be, a modern-day bidding experience can be very different from what may be envisioned. What happens when a piece of machinery breaks down or a quick fix is needed to keep production going? Maintenance personnel often succumb to the temptation of rigging a temporary solution by using machinery in a service for which it is not designed. Other times, they can improvise modification to industrial supplies in order to get a job done quickly.

What happens when a piece of machinery breaks down or a quick fix is needed to keep production going? Maintenance personnel often succumb to the temptation of rigging a temporary solution by using machinery in a service for which it is not designed. Other times, they can improvise modification to industrial supplies in order to get a job done quickly.